Pulp & Paper Mill

Hot Caustic Line Replacement in Paper Mill

Case Study Nº

51

Customer

Svetlogorskiy Mill

Russia

|

2015

Working Conditions

Non-pressure, high temperature and scrubber water

Pexgol Pipes

Pexgol 160 mm Class 15

Application

Alkali transportation in caustic and regeneration workshop

Lenght

13 m

Categories

The Challenge

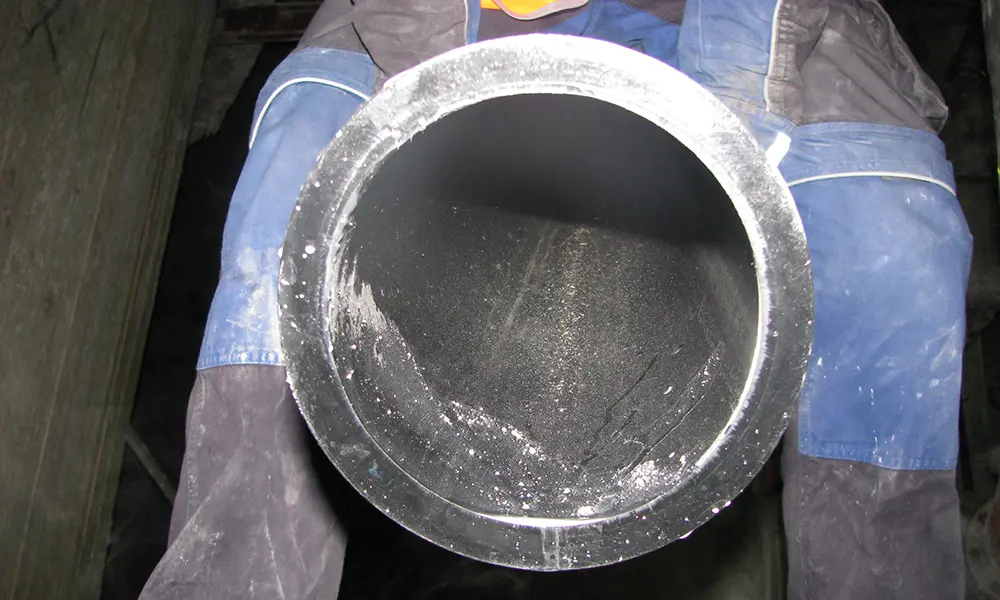

At Svetlogorskiy Mill Paper Plant they needed to repair their stainless steel pipes a few times a year, since they were transporting alkali at very high temperature.

The main challenge for the line was the sedimentation issues.

Pexgol Solution

The client decided to replace the stainless steel pipes with Pexgol pipes. Thanks to it smooth inner surface, sedimentation is not a problem and as a consequence requires less maintenance.

The line has been installed since 2015 and it stills shows amazing results.

Related Case Studies

Compressed Air System

Rav-Gon Printing House

Israel

|

2020

Pexgol Piping for Fire Network System Expansion

Wall

Argentina

|

2023