Compressed Air Transportation

Replacement of a HDPE Pipe for a Pexgol Pipe

Case Study Nº

41

Customer

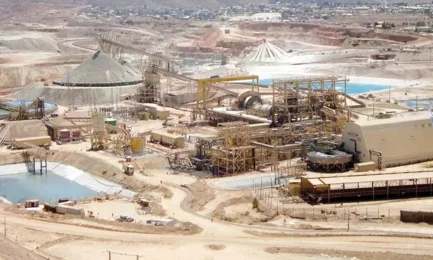

Saucito S.A. de C.V. Mine

Mexico

|

2017

Working Conditions

Pressure 205-262 psi; Temperature 60°C to 71°C / 140° F to 159.8°F.

Pexgol Pipes

Pexgol SDR 6 110×18.3.

Application

Compressed air transportation.

Lenght

600 meters.

Categories

The Challenge

The client decided to replace their current HDPE pipe lines which transported compressed air at 60°C to 71°C / 140° F to 159.8°F.

The reason for replacing the HDPE pipes was serious leaks on the thermo-fusion joints.

As one possible reason for these failures, the client pointed out that the maximum allowed temperature of the HDPE pipes was just up to 45°C / 113°F.

Pexgol Solution

In order to solve this problem, Saucito Mine decided to replace their HDPE pipes for Pexgol pipes.

Beside their high temperatures resistance up to 110°C / 230°F, Pexgol pipes are not connected by thermo-fusion joints. They are supplied in 600 meters long sections with very few connections.

The installation was fast and efficient and no sophisticated tools were necessary.

Related Case Studies

Compressed Air System

Rav-Gon Printing House

Israel

|

2020

Mining Drainage Lines

Lundin Mining – Alcaparosa Mine

Chile

|

2019