Fewer Shutdowns, Greater Efficiency: Pexgol in the Salt Industry

Pexgol extends pipe lifespan and reduces maintenance in salt production.

Case Study Nº

173

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Sales del Istmo (SISA), a producer of iodized and fluoridated salt in Veracruz, Mexico, was facing recurring issues with scaling inside their stainless steel pipes used to transport mother liquor—a solution with a high concentration of rock salt dissolved in water.

This scaling led to frequent pipe blockages, causing repeated shutdowns for maintenance or pipe replacement. Plant personnel were forced to strike the stainless steel pipes to restore flow, which accelerated wear and increased operational costs.

The company needed a solution that would extend the service life of the pipelines and prevent costly production interruptions.

The Solution

To tackle this issue, Sales del Istmo decided to install a 12-meter section of 6” Pexgol SDR 11 pipe, aiming to reduce scaling and increase uptime.

Thanks to its molecular structure and low internal roughness, Pexgol prevents buildup and ensures consistent flow.

Test Results

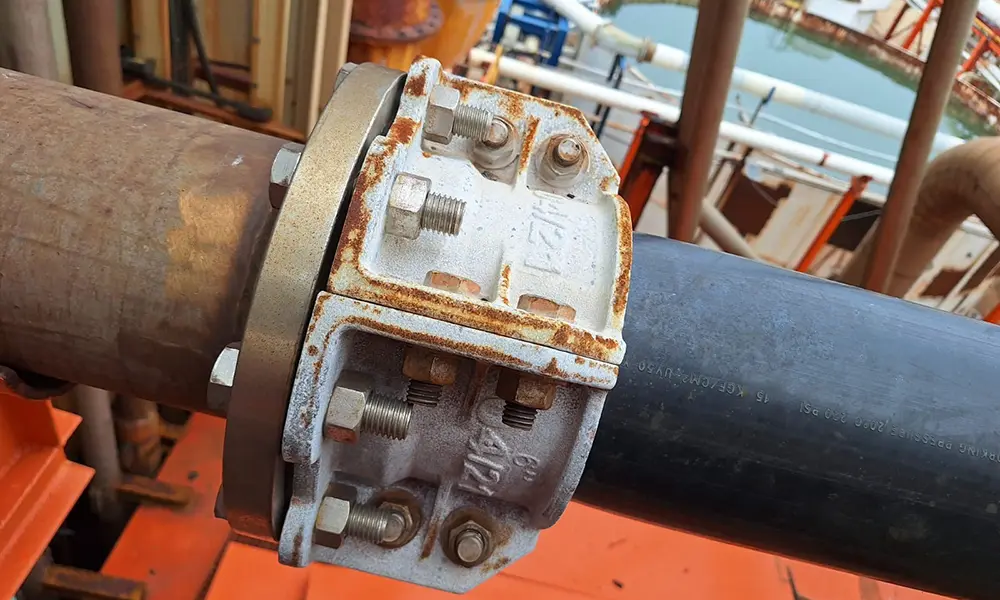

After 9 months of continuous operation, the pipe was dismantled and found to be completely free of scaling, proving its effectiveness under operating conditions of 4 bar (58 psi) and 80°C (176°F).

Installation Process

- The installation was carried out with the support of the plant’s internal team, without requiring a crane to lift the pipe to the upper structure.

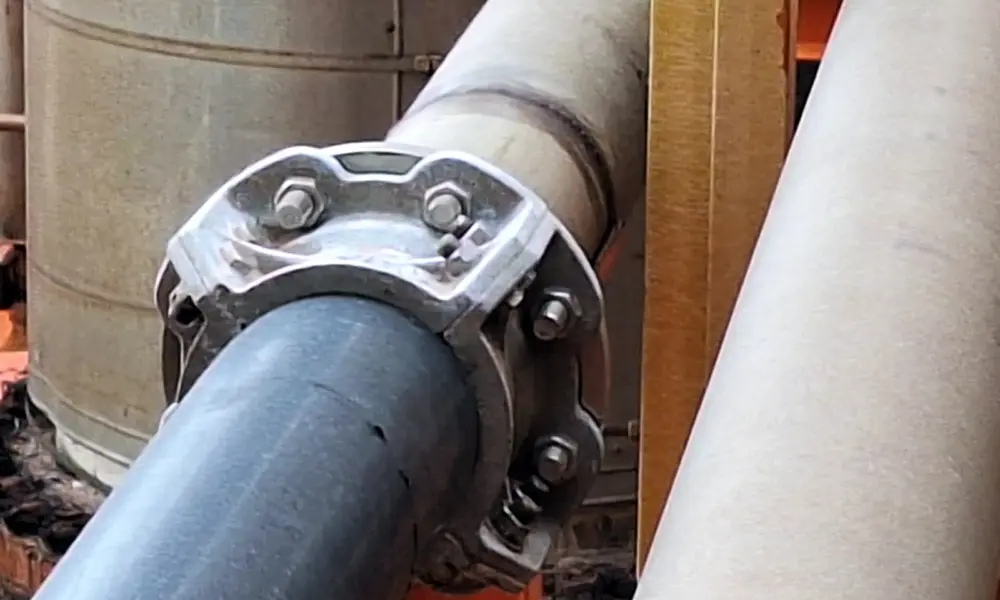

- Despite having no prior experience with plastic piping, the team was able to cut and assemble the GP flanged couplings in record time.

Thanks to this successful implementation, Sales del Istmo has significantly reduced maintenance costs, minimized production downtime, and improved operational efficiency with a reliable and long-lasting solution.

Related Case Studies

Hot Water Distribution for Solar Technology

|

Water Lines – High Pressure Water Feed Lines

|