Replacement of a Steel Spool with Pexgol

Substitution of a Steel Spool for PE-X Coated for Pumping Formation Water.

Case Study Nº

106

Customer

Enap Sipetrol

Ecuador

|

2021

Working Conditions

Pressure: 10 PSI | Temperature: 71°C / 160°F

Pexgol Pipes

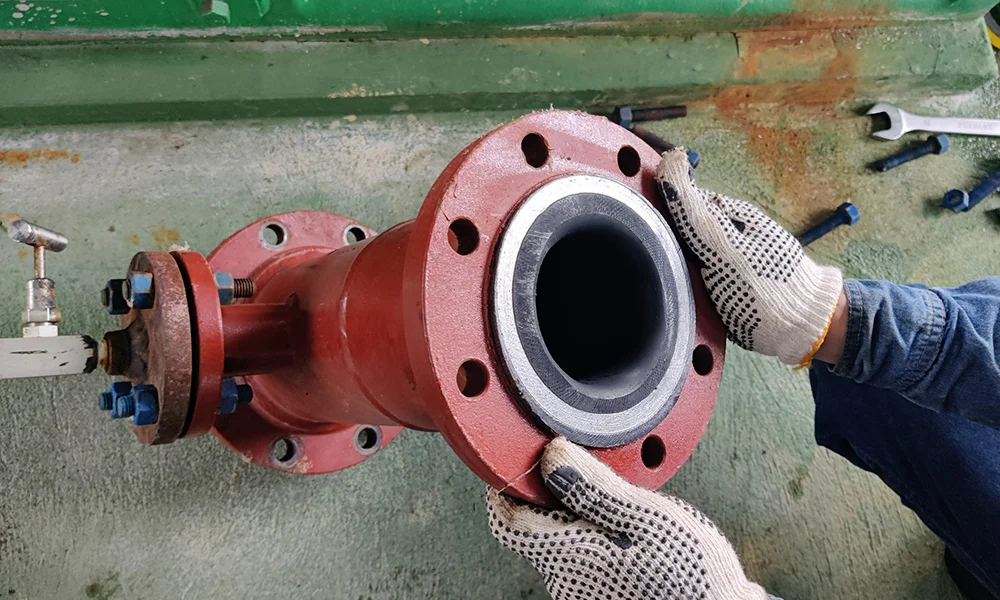

6”x4” steel eccentric reducer coated in Pexgol

Application

Formation water pumping

Lenght

n/a

Categories

The Challenge

Enap Sipetrol Ecuador, is a branch of the Chilean state oil company Enap, is the operator and owner of 42% of Block 28 in the southeastern area of Ecuador.

In their process plant where it was necessary to transport formation water, they had a steel spool coated internally with epoxy paint and it corroded easily due to the aggressiveness of the fluid.

Pexgol Solution

The client decided to replace the steel spool with Pexgol. It was installed in October 2021 and inspected in March 2022 and no type of corrosion or adhesion of solids was observed.

Related Case Studies

Compressed Air Transportation

Saucito S.A. de C.V. Mine

Mexico

|

2017

Transport of Muddy Water in a Palm Oil Processing Plant

La Gloria

Colombia

|

2020

Water Transportation on a Mining Road

CODELCO – Andina Mine

Chile

|

2019

Transporting Brine at High Pressure

Mekorot

Israel

|

2020

Potable Water Supply on Harsh Terrain

Mekorot / Beit Shemesh Water Company

Israel

|

2017

Transport of Compressed Air for Underground Mine

HMC Gold

Chile

|

2021