Transport of Compressed Air

Installation of a Pexgol Line 200 Meters Deep at an Underground Mine

Case Study Nº

66

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

The Meridian Mine (Faena El Peñón) required the installation of a line for the transport of compressed air from the surface (horizontal), crossing roads of mining vehicles, ending 200 meters deep inside an underground mine through a vertical chimney.

The line had to withstand 10 bar of pressure.

Pexgol Solution

The client decided to install a 160 mm (6”) Pexgol pipe class 15 SDR 11 of 1800 meters in coils of 600 meters each.

Pexgol pipe was selected due to it advantages:

- Less joints were needed, contributing to saving costs and giving more reliability to the line.

- Resistance to mechanical stresses involved in installing at mining crossroads, using a 1.5 meter ditch and filling with material from the same ditch, without using a steel jacket.

- Resistance to changes in ambient temperature (5°C to 30°C).

- Creep resistance.

The installation was simple: only 4 mechanical connections were used, selected by the mining company without using special tools. If HDPE pipes were used, about 150 mechanical connections would have been required.

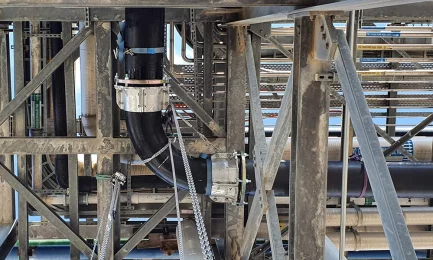

Also, to support the Pexgol pipes in the upper zone, before entering the underground mine by the chimney, a mechanical system designed by the mining company was incorporated.

Related Case Studies

Carriage of Chemicals at Sea Port

|

Transportation of Alcohol for the Production of Rum and Brandy

|

Mining Drainage Lines

|

Industrial Waste Water to MBR Treatment Facility

|