INCLINED AND DEWATERING PIPES, HIGH GRADIENT SUPPLY LINES

Design Considerations

All these type of pipes should be axially restrained at the top and bottom of the line.

The pump rests on the ground. The weight of the pump and water column is not supported by the pipe.

Defining the design temperature

See Point 1 of “Pexgol Pipes design considerations”

Selecting the Pexgol pipe for dewatering/uphill pipes

Design example:

- Required flow rate: 150 cubic meters per hour Pipeline goes from an altitude of 2100 m to an altitude of 2235 m

- Line length: 500 m

- Ambient temperature: 40°C

- Fluid temperature: 20ºC

- The pipe can be installed above ground or covered by 0.9 m of soil.

Calculate the line pressure by grade line calculation or according to any other applicable method.

Calculate the static pressure at the lowest point of the pipeline taking into account the fluid density. For water, multiply the altitude difference (in meters) in the line by 10.

The result is in bar. Please note that the lowest point is not necessarily at the bottom of the pipeline.

In this example:

2235 – 1100 = 135 m

135 = 13.5 bar

Choose the appropriate Pexgol pipe class from table 9.1 by looking at the design temperature. Select the Pexgol pipe class which has a higher working pressure than the calculated value in section 3.1. The additional pressure margin will be used for the head losses.

For design temperature for above ground installation please see “Defining design temperature”.

Selected pipe class for buried pipes installation:

Class 19. Working pressure – 14.9 bar at 40°C:

Selected pipe class for above ground installation:

Class 24: Working pressure -15 bar at 60°C.

Alternative pipe – Class 30. Working pressure –

18.9 bar at 60°C. Design temperature for buried

pipes is 40°C.

Design example with alternative pipe class 24

Calculate the pressure margin and the allowable Head losses coefficient J;

Pressure margin for above ground installation is

15 – 13.5 = 1.5 bar = 15 m

J = 15 x 100/500 = 3%

Pressure margin for the alternative pipe for above ground installation is:

18.9 – 13.5 = 5.4 bar = 54 m

J = 54 x 100/500 = 10.8%

Pressure margin for buried pipes installation

14.9 – 13.5 = 1.4 bar = 14 m

J = 14 x 100/500 = 2.8%

Pressure margin for the alternative pipe for buried pipes installation:

18.7 – 13.5 = 52 bar = 52 m

J = 52 x 100/500 = 10.4%

Select the pipe diameter according to the calculated J and the flow rate. The selected pipe diameter for above ground installation is 200 class 24.

The alternative pipe diameter for above ground installation is 180 class 30.

The selected pipe diameter for buried pipe installation is 200 class 19.

The alternative pipe diameter for buried pipe installation is 160 class 24.

Advantages of the alternative pipes:

- Smaller diameter allows transportation of longer pipe sections that results in cheaper transportation.

- Cheaper pipe per meter length.

- Disadvantage: higher head losses.

The line designer should include in the line the all the required accessories including air relief valves and drain valves.

If the overall altitude difference in the line is much higher that the maximum allowable altitude difference H of the highest Pexgol SDR available, the line should be designed using booster pumps.

Selecting the Pexgol pipe for a downhill pipeline using a full cross-section flow design. In a full cross-section flow design the pipe has to support the full static pressure (liquid column) of the line.

Design example:

- The pipeline goes down a slope from an altitude of 2250 m to an altitude of 2100 m

- Required flow rate: 150m³ per hour Line length: 1500 m

- Fluid temperature: 20ºC

- Ambient temperature: 40°C

The pipe can be installed above ground or covered by 0.9 m of soil.

Calculate the line pressure by grade line calculation or according to any other method. Calculate the static pressure at the lowest point of the pipeline taking into account the fluid density. For water – divide the altitude difference (in meters) in the line by 10. The result is in bar. Please note that the lowest point is not necessarily at the bottom of the pipeline. In this example the lowest point in the line is located at the end of the line:

2250 – 1100 = 150 m = 15.0 bar

Choose the suitable Pexgol pipe class from table 11.2: “Allowable working pressures [bar] for conveying water in Pexgol pipes” by looking at the design temperature. Select the Pexgol pipe class which has the same or slightly higher working pressure than the calculated value in section.

Design temperature for above ground installation is 40° +20°C . Selected pipe class for above ground installation:

For a full cross-section flow design the pipe should be Pexgol class 24 in order to allow a working pressure of 15 bar at 60°C.

Calculate the allowable head losses coefficient J based on the altitude difference in the line and the line length: Altitude difference is: 150 m J = 150 x 100/1500 = 10%

For a full cross-section flow design, select the suitable pipe that can transport the required flow with the calculated value of J. Selected pipe SDR for above ground installation is 160 class 24. Selected pipe class for buried pipe installation is 160 class 19.

Check the value of the expected surge pressure (water hammer) against the maximum permissible. Total occasional pressure, which is 2.5 the working pressure in the design temperature.

For the 160 class 24, the Line velocity V = 4 m/sec. According to the table n°32.1: “Low surge pressures expected in Pexgol pipes” the surge pressure for class 24 is 3 bar for V = 1 m/sec. for V = 4 m/sec. the surge pressure value will be 4 x 3 = 12 bar.

The total occasional pressure will be 15 + 12 = 27 bar. The maximum permissible total occasional pressure in class 24 at 60°C is 15 x 2.5 = 37.5 bar.

Conclusion: the 160 class 24 is O.K. or the 160 class

19, the line velocity V = 3.44 m/sec.

According to the table n°32.1: “Low surge pressures expected in Pexgol pipes”, the surge pressure for class 24 is 3.2 bar for V = 1 m/sec so for V = 3.44 m/sec the surge pressure value will be 3.44 x 3.2 = 11 bar. The total occasional pressure will be 15 + 11 = 26 bar. The maximum permissible total occasional pressure in class 19 at 40°C is 14.9 x 2.5 = 37.25 bar. Conclusion: the 160 class 19 is O.K.

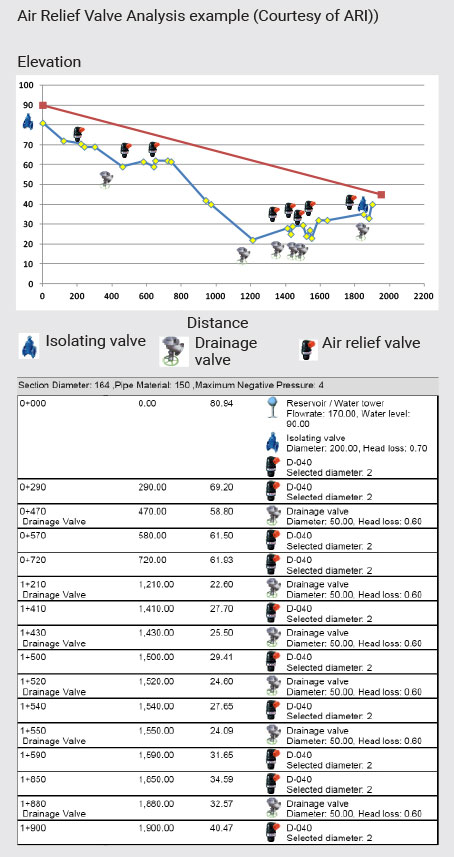

Air relief valves

Air relief valves are required in any pipeline material including Pexgol.

The line designer should include in the line the all the required accessories including air relief valves and drain valves.

As a service to our customers, Pexgol application engineers can perform the analysis of the line in cooperation with A.R.I. Israel and supply a drawing with the location of the air relief valves. Golan supplies the air relief valves and the saddles/fittings required for connecting the line accessories to the Pexgol pipes.

The following data is required for the analysis:

1. List of key points along the line in Excel file or PDF/ DWG drawing of the line with the following details:

- Name of the point.

- Location of the point: distance from the beginning of the line and height above a reference point.

- Type and functionality of each fitting: drain, cut- off valve, pressure reducer, outlet connection to consumer (indicate flow rate), etc.

2. Working conditions:

- Flow direction

- Discharge rate

- Inlet/outlet pressures

Selecting the Pexgol pipe for downhill single slope pipeline using a partially filled cross-section flow design

Please note that this type of design requires a skilled designer so the following information should be considered as guidelines only.

In case of a partially filled cross-section flow design, the pipe is to be designed so that it will be in a low pressure (close to an atmospheric pressure) in all or most of its length. This design allows the use of a lower pipe class of with a larger OD and this might be problematic for transportation.

Calculate the allowable head losses coefficient J based on the altitude difference in the line and the line length.

Calculate the ID of the pipeline (according to Hazen – Williams C = 155 or any other formula).

In order to make sure that flow regime will be a partially filled cross-section, the selected actual ID of the line should be at least 25% higher than the calculated pipe ID according to previous design example.

Selecting the Pexgol pipe class: It is a good practice to design Class 15 in order to allow full vacuum resistance and possibility of transporting long pipe sections. Lower

pipe classes should be avoided in this case. Higher pipe classes can be designed for transporting longer sections while maintaining the required minimum ID for the partially filled cross-section low design.

Pexgol pipe for downhill single slope pipeline can be designed using a partially filled cross-section flow design

Each top point in the line should be vented so that the pressure there is atmospheric pressure.

Each valley is actually a siphon so that the height of the fluid column above the bottom of the valley is calculated from the previous top point in the line.

In some cases, the pipe class might have to be higher than class 15, depending on the local static pressure.

Installing the Pexgol pipe

Pexgol pipes can be towed upwards from the bottom of the line or it is possible to slide the pipe down from a high point.

Empty Pexgol pipes can be towed up to the top of the line in very long sections. Table 87.1 presents the maximum allowable length of an empty Pexgol pipe that is allowed to be towed or slid to its final location, depending on the design temperature.

The maximum allowable length is the same for all Pexgol pipe classes.

The required towing force can be calculated by multiplying the weight of the pipe by the friction coefficient of 0.5.

If the pipe consists of more than one sections, the sections can be connected temporarily during towing.

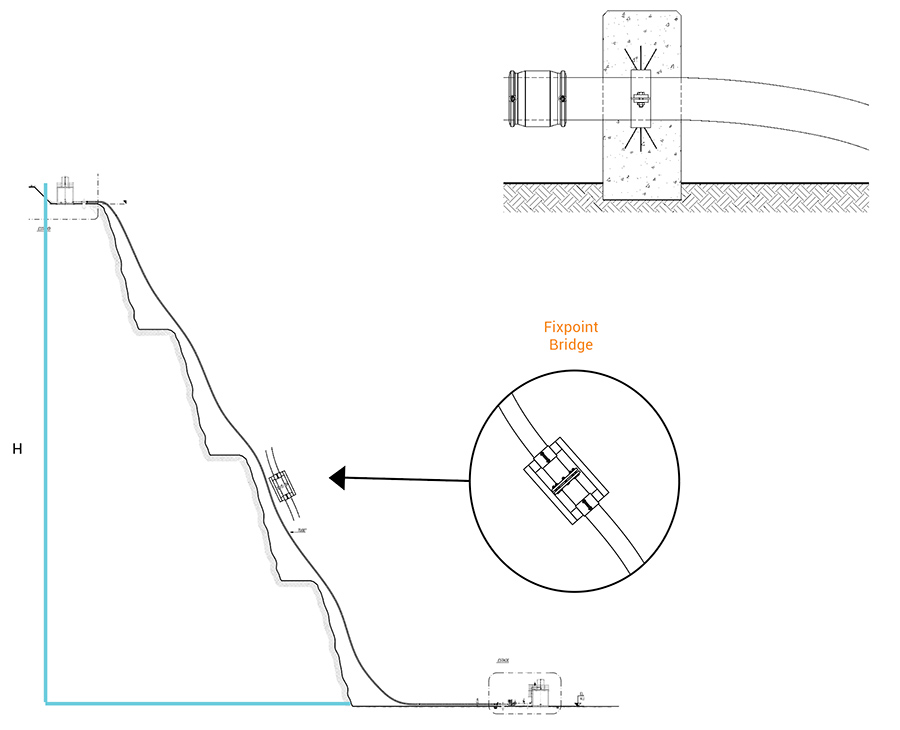

If the pipe sections are already connected by fittings, they should be secured and protected by fixpoint bridges.

Securing inclined Pexgol pipes

- The top and bottom ends of the Pexgol pipeline should be anchored by a fixpoint (see drawing).

- The Pexgol pipeline can be laid uphill or downhill in a long continuous section, without any fixpoint between the top and bottom ends.

- There is no limitation on the total pipe length.

- It is recommended to design the pipe with an additional 1 – 2% slack in order to reduce potential axial contraction forces.

- The weight of the pipe might increase due to accumulation of soil or snow on top of it. This additional weight will be balanced by the increasing friction between the pipe and the ground.

Table 57.1: Towing of empty Pexgol pipe - maximum allowable length (metres)

Towing of empty Pexgol pipe - maximum allowable length (meters)

| Pipe | 0°C | 10°C | 20°C | 30°C | 40°C | 50°C | 60°C |

|---|---|---|---|---|---|---|---|

| All Classes | 1150 | 1100 | 1000 | 850 | 750 | 650 | 600 |

Restraining of fittings along the pipeline

- In slopes of less than 40°, all mechanical couplers (flared ends, flange couplers etc.) should be restrained by floating fixpoint devices like Golan’s fixpoint bridge. Electrofusion couplers can be installed without a floating fixpoint device.

- In slopes above 40°, all type of fittings (including electrofusion couplers) should be restrained by floating fixpoint devices.

- When installing a repair fitting, the pipe can be secured by a fixpoint bridge prior to cutting the pipe.