WATER HAMMER

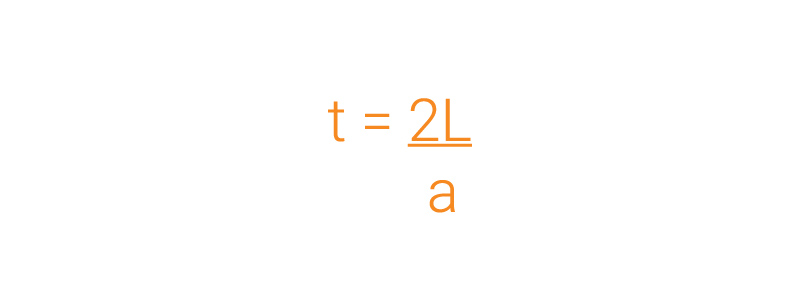

Water hammer is a series of pressure pulsations, of varying magnitude, above and below the normal pressure of the liquid in the pipe. The amplitude and periodicity depends on the extinguished velocity of the liquid, as well as the size, length and material of the pipeline. Shock results from these pulsations when any liquid, flowing with a certain velocity, is stopped in a short period of time. The pressure increase, when flow is stopped, is independent of the working pressure of the system. The surge pressure in any pipeline occurs when the total discharge is stopped in a period of time, equal to or less than the time required for the induced pressure wave to travel from the point of valve closure to the inlet end of the line and return. This time is:

Where:

t = Time for pressure wave to travel the length of the pipe and return (sec.)

L = Length of pipe line (m)

a = Velocity of pressure wave (m/sec)

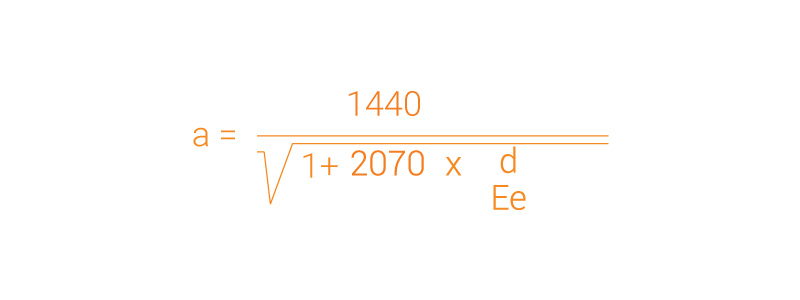

When the liquid in the pipe is water, the velocity of the pressure wave “a” is determined by the following equation:

Where:

a = Velocity of pressure wave (m/sec).

Kbulk = Bulk modulus of fluid (for example: 2,070 MPa for water at 20°C)

d = Inside diameter of pipe (mm)

e = Thickness of pipe wall (mm)

E = Instantaneous (short term) modulus of elasticity (MPa) for the pipe material (obtained from Tensile tests)

The surge pressure caused by water hammer is determined by the following equation:

Where:

P = Surge pressure (bar)

ρ = Fluid density (for example: 1 gr/cm³ for water at 20°C)

a = Velocity of pressure wave (m/sec)

V = Velocity of water stopped = line velocity (m/sec)

g = Acceleration caused by gravity (9.81 m/sec²)

Pressure caused by water hammer can be minimized by increasing closure times of valves to a value greater than 2L/a.

For example, when the closure time is 10 times 2L/a, the pressure surge can be 10% – 20% of the surge caused by closure in a time equal to or less than 2L/a.

The value of the short-term modulus of elasticity E for Pexgol pipes is much lower than the value of E for steel pipes, concrete pipes or HDPE pipes. Since the velocity a of the pressure wave is related to the short-term modulus of elasticity E, the velocity a decreases when the value of E is lower.

In order to determine the resistance of the pipe material to the water hammer phenomenon, the total occurring pressure (surge pressure + working pressure) should be calculated and compared to the maximum allowable total occurring pressure in each pipe material. The resistance of HDPE pipes depends on the nature of the water hammer. In case of recurring water hammer shock waves, HDPE pipes are limited to a maximum total occasional pressure of only 1.5 times the working pressure. Because of the flexibility and resilience of Pexgol pipes, the surge pressures caused by the water hammer are much reduced. Furthermore, because of the cross-linked structure, the Pexgol pipe can withstand a total transient pressure (recurring or occasional surge pressure + working pressure) at least 2.5 times the design pressure in the relevant temperature.

Water Hammer Calculation for Different Pipe Materials

The following comparison examples show the pressure surges caused by the water hammer for various pipes, which are considered for the same application. In all following examples:

- The line is horizontal; line length is 2,200 m.

- The flow rate is 150 cubic metre per hour, head losses are 5%.

- The line is designed for a pump pressure of 11 bar.

- The fluid temperature: 20 °C.

The pipes calculated for this application are as follows:

- Steel pipe 6” schedule 40, buried pipeline or above-ground installation.

- PE 3408 6” DR 11, buried pipeline.

- PEX 160 mm SDR 13.6 Class 12, buried pipeline.

- PE 4710 6” DR 13.5, buried pipeline.

- PEX 180 mm SDR 11 Class 15, Above ground installation, ambient temperature 20°C, design temperature is 30°C.

- PEX 180 mm SDR 9 Class 19, Above ground installation, ambient temperature 40°C, design temperature is 40°C.

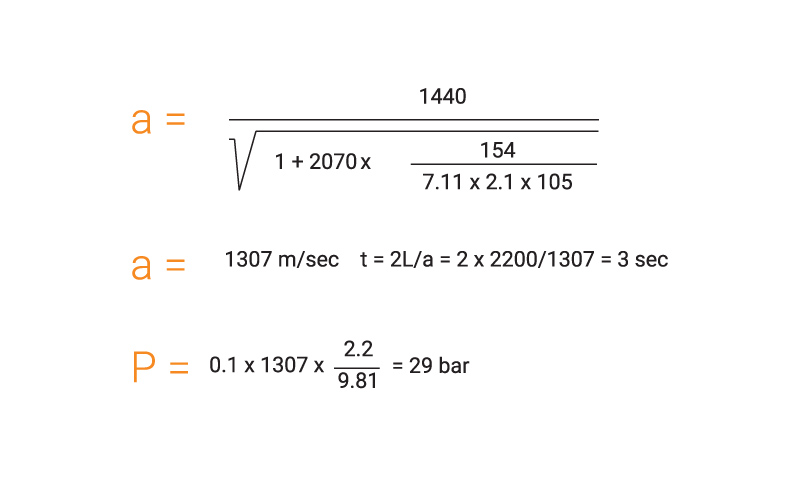

1. Steel pipe 6” sch. 40

Buried pipeline or above ground installation.

OD: 6.625” (168.3 mm) | w.t. 7.11 mm | d = 154 mm | V = 2.2 m/sec | E = 210,000 MPa

P = Surge pressure (bar) 29 bar.

Total transient pressure: Surge pressure (29 bar) + pump pressure in the line (11 bar) is 40 bar.

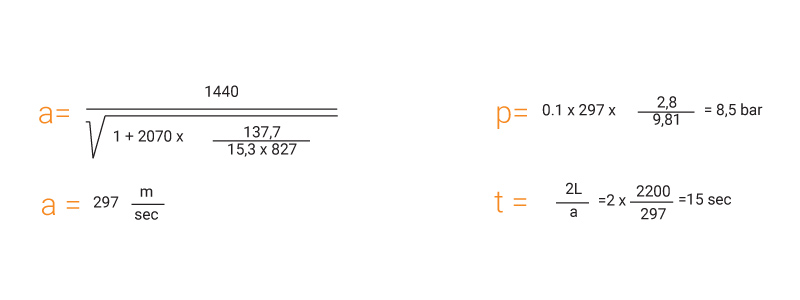

2. PE 3408 6” DR 11

Buried pipeline. Maximum allowable working pressure of the pipe is 11 bar (160 psi) at 20°C.

Maximum allowable total transient pressure: 16.5 bar (240 psi).

OD: 6.625” (168.3 mm) | w.t.: 0.602” (15.3 mm) | d: 137.7 mm | V = 2.8 m/sec, E = 827 MPa at 20°C

P = Surge pressure (bar) 8.5 bar, total transient pressure: 11 + 8.5 = 19.5 bar.

Total transient pressure: Exceeds the maximum allowable total transient pressure for this pipe material.

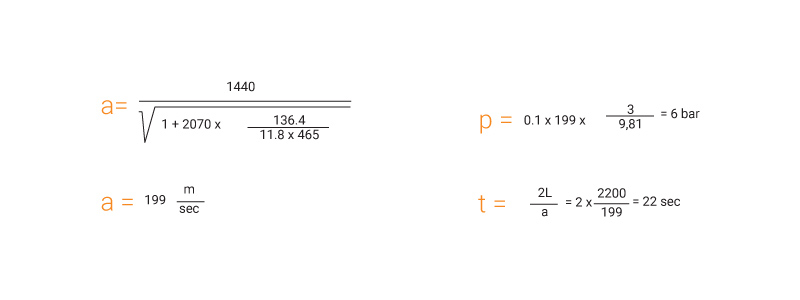

3. Pexgol 160 mm SDR 13.6 Class 12

Buried pipeline: Maximum allowable working pressure of the pipe is 12 bar at 20°C. Maximum allowable total transient pressure: 30 bar.

OD: 160 mm | w.t.: 11.8 mm | d: 136.4 mm | V = 3 m/sec, E = 465 MPa at 20°C

P = Surge pressure (bar) 6 bar, total transient pressure: 12 + 6 = 18 bar

Total transient pressure: Is much lower than the maximum allowable total transient pressure (30 bar).

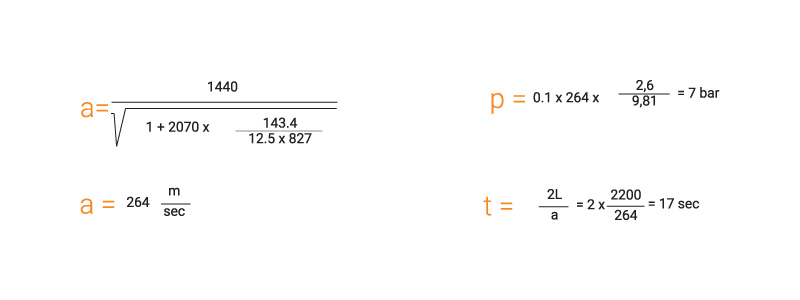

4. PE 4710 6” DR 13.6

Buried pipeline: Maximum allowable working pressure of the pipe is 11 bar (160 psi) at 20°C.

Allowable total pressure during recurring surge is 16.5 bar.

OD: 6.625” (168.3 mm) | w.t.: 0.491” (12.5 mm) | d: 143.4 mm | V = 2.6 m/sec | E = 827 MPa at 20°C

P = Surge pressure (bar) 7 bar, total transient pressure: 11 + 7 = 18 bar.

Total transient pressure: Exceeds the maximum allowable total transient pressure for this pipe material.

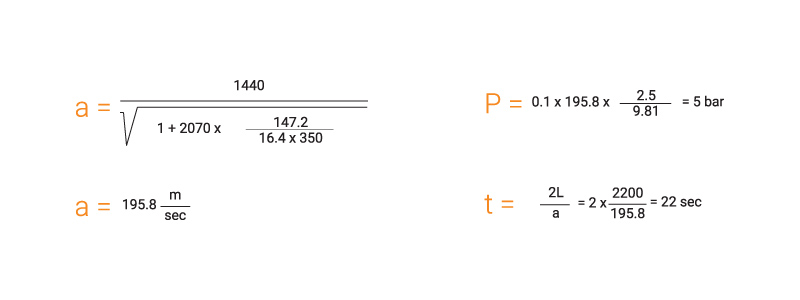

5. Pexgol 180mm SDR 11 Class 15

Above ground installation: ambient temperature is 20°C, design temperature is 30°C. Maximum allowable working pressure of the pipe is 13 bar (193 Psi) at 30°C. Maximum allowable total transient pressure: 30 bar.

OD: 180 mm w.t.: 16.4 mm d: 147.2 mm | V = 2.5 m/sec | E = 350 MPa at 30°C

P = Surge pressure (bar) 5 bar, total transient pressure: 13.3 +5 = 18.3 bar

Total transient pressure: Is much lower than the maximum allowable total transient pressure (30 bar).

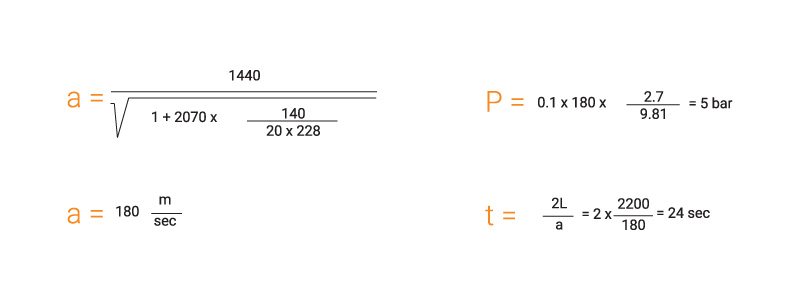

6. Pexgol 180 mm SDR 9 Class 19

Above ground installation: ambient temperature is 40°C, design temperature is 40°C. Maximum allowable working pressure of the pipe is 11 bar at 40°C. Maximum allowable total transient pressure: 30 bar.

OD: 180 mm | w.t.: 20 mm | d: 140 mm | V = 2.7 m/sec | E = 228 MPa at 40°C

P = Surge pressure (bar) 5 bar, total transient pressure: 11 + 4 = 15 bar

Total transient pressure: Is much lower than the maximum allowable total transient pressure (30 bar).

Conclusions

- The surge pressure caused by the water hammer in steel pipes is at least three times higher than the surge pressure in Pexgol pipes.

- The surge pressure caused by the water hammer in HDPE pipes could sometimes be too high.

- Pexgol pipes have a high margin for surge pressures in all temperature range and pipe classes.

The expression for a = the velocity of pressure wave is a function of the short term Modulus E and the dimension ratio d/e, which is the same for each pipe class:

d/e = (D-2xe)/e = (D/e) – 2 = SDR-2

It is possible to calculate the values for a for each pipe class.

In the following table (48.1), the values of the pressure velocity a were calculated for the following design temperatures:

- 20°C – for buried pipes

- 30°C – for above ground pipes at ambient temperature of 20°C

- 40°C – for above ground pipes at ambient temperature of 40°C

The values of P were calculated for line velocity of

1.0 m/sec.

Table 48.1 shows the low surge pressures expected in Pexgol pipes.

Table 48.1: Surge pressures in Pexgol pipes (according to water velocity of 1 m/sec)

| Pipes Class | SDR | E=465MPa | E=350MPa | E=228MPa | |||

|---|---|---|---|---|---|---|---|

| 20ºC | 30ºC | 40ºC | |||||

| a [m/sec] | Surge pressure [bar] | a [m/sec] | Surge pressure [bar] | a [m/sec] | Surge pressure [bar] | ||

| 6 | 26 | 139 | 1.4 bar | 120 | 1.2 bar | 97 | 1.0 bar |

| 8 | 21 | 156 | 1.6 bar | 135 | 1.4 bar | 109 | 1.1 bar |

| 10 | 16.2 | 180 | 1.8 bar | 156 | 1.6 bar | 126 | 1.3 bar |

| 12 | 13.6 | 198 | 2 bar | 173 | 1.8 bar | 140 | 1.4 bar |

| 15 | 11 | 225 | 2.3 bar | 196 | 2.0 bar | 158 | 1.6 bar |

| 19 | 9 | 254 | 2.6 bar | 221 | 2.3 bar | 179 | 1.8 bar |

| 24 | 7.4 | 288 | 2.9 bar | 251 | 2.3 bar | 204 | 2.1 bar |

| 30 | 6 | 332 | 3.4 bar | 290 | 3.0 bar | 236 | 2.4 bar |

The value of a = Velocity of pressure wave was calculated using the instantaneous Modulus of Elasticity. Please note the surge pressure P is in direct linear relation to the value of the line velocity V.

Therefore, values for different surge pressures for the same pipe class can be calculated by changing the values of the Line velocity V.

Example: Calculating the surge pressure in paragraph 4. Pexgol 180 mm SDR 9 Class 19.

- Above ground installation ambient temperature is 40°C.

- Fluid temperature is 20°C

- Design temperature is 40°C.

- Design pressure of the pipe is 14.9 bar at 40°C.

- Maximum allowable total transient pressure is 30 bar.

OD 180 mm | w.t. 20.1 mm | d = 139.8 mm | V = 2.7m/sec

From the table: “Low surge pressures in Pexgol pipes”, the surge pressure for class 19, velocity of 1 m/sec and design temperature of 40°C is 1.8 bar.

For the Pexgol 180 mm class 19 which has a velocity of 2.7 m/sec, the surge pressure will be: 1.6 x 2.7/1 = 4.9 bar

For water density higher than 1.0, divide the value of the Velocity of the pressure wave a (taken from the table: “Low surge pressures in Pexgol pipes”) by the square root of the actual water density.

For fittings on the line please contact Pexgol team.