Vertical Solution for Mine Dewatering in Fresnillo

A Challenging Project That Eliminated Booster Stations Thanks to Pexgol’s Flexibility.

Case Study Nº

179

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

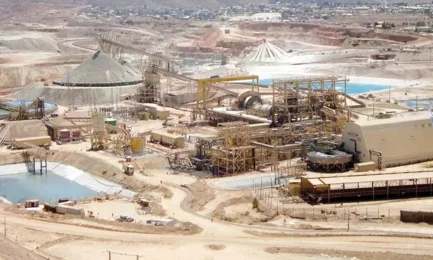

Minera Fresnillo Plc, the world’s largest silver producer and one of Mexico’s top gold producers, faced a new challenge in its underground operation at the San Alberto Ramp. It was necessary to pump mine water from level -695 to level -610, where infrastructure already existed to convey the water to the surface.

Traditional solutions involved installing conventional piping along horizontal tunnels, which meant greater distances, higher energy consumption, and the need for intermediate booster stations. Additionally, the environmental conditions—temperatures up to 32°C and 100% relative humidity—added complexity to the project.

The Solution

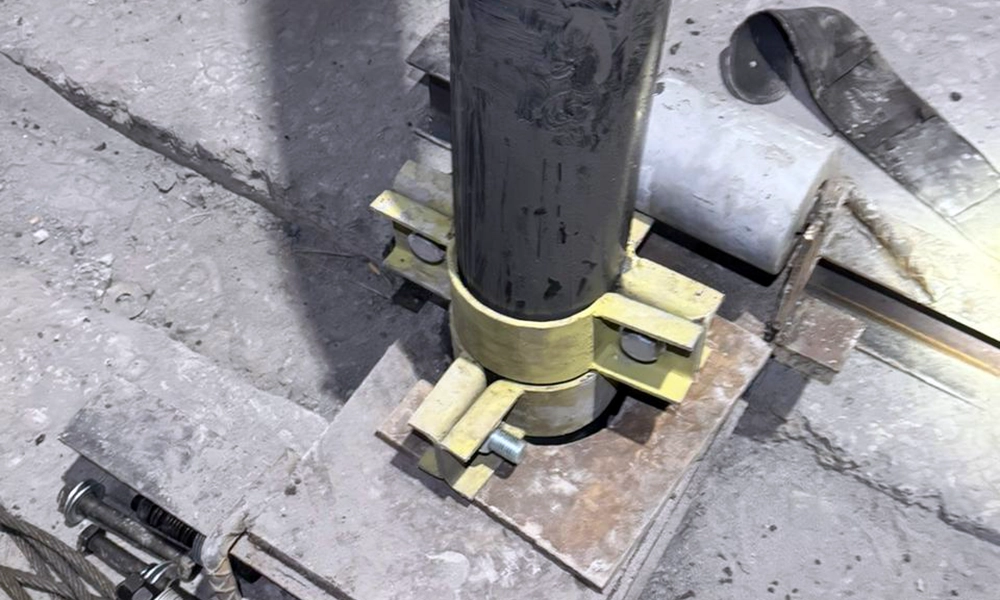

Thanks to the unique properties of Pexgol 6” SDR9 pipe, a direct vertical installation of 130 meters (426 ft) elevation difference was implemented through two 10-inch boreholes, without requiring perfect borehole alignment. The system’s flexibility andmechanical strength allowed it to adapt precisely to the borehole conditions.

The installation was executed with a single submersible pump located at level -695, which pushed the water directly to level -610, completely eliminating the need for intermediate booster stations. Main accessories included flanged couplings and load clamps.

Despite high humidity and limited tunnel space, the installation of both lines was completed in just 10 effective hours. The pipes were unrolled and inserted simultaneously into the inclined borehole without compromising personnel safety.

A key factor in the project’s success was the technical support provided by the Pexgol team. Given the lack of prior experience with vertical installations, training sessions and planning meetings were conducted weeks in advance, ensuring the crew was fully prepared and confident to carry out the installation

Related Case Studies

Fast and Reliable Solution for Winemaking Processes

|

“Threading” Pexgol Pipes

|

Водоснабжение для пожарных сетей

|

Efficient Choice: PE-X Pipe for the Palm Industry

|