Overcoming Corrosion Challenges in the Oil Industry

Overcoming Corrosion Challenges in the Oil Industry

Case Study Nº

162

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Petróleos Sudamericanos S.A., a company with over 30 years of experience in oil and gas exploration and production in Argentina, was facing significant problems with its existing infrastructure for oil and water transportation. The current line, composed of recovered 2 7/8-inch tubing, suffered from internal and external corrosion, which not only decreased operational efficiency but also posed environmental risks due to potential leaks. Additionally, the pipe’s transport capacity was insufficient to handle the increase in flow from the producing wells connected to the collector.

The Solution

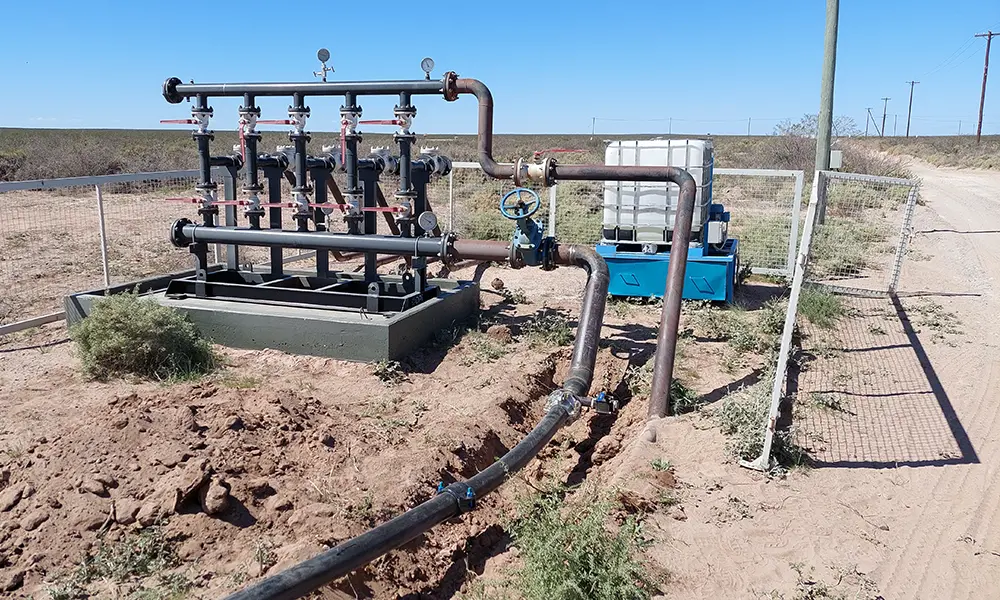

To resolve these issues, Petróleos Sudamericanos decided to replace the existing line with 110 mm, class 30 Pexgol pipes, known for their high resistance to chemicals and corrosion. The new installation aimed to improve operational efficiency, increase transport capacity, and reduce environmental risks associated with leaks. Double mechanical connectors and flanged couplings were used to ensure a safe and efficient installation.

The installation of the five 350-meter rolls of pipe was completed in a record time of 3 days, meeting the client’s stipulated deadlines. This process included making two road crossings without the need for casing pipes, which simplified the installation process and minimized disruption to existing operations. The new Pexgol pipe not only eliminated corrosion issues but also provided a lightweight and easyto-handle solution, allowing for quick installation and improving operational safety.

The project demonstrated Pexgol’s ability to meet the demands of the oil industry, offering a durable and efficient solution for hydrocarbon transportation. The installation met high operational and safety standards, significantly reducing maintenance costs and environmental risks.

Related Case Studies

Well Drainage at Mining Dam

|

Fish Oil Transport at 36°C / 96.8°F

|