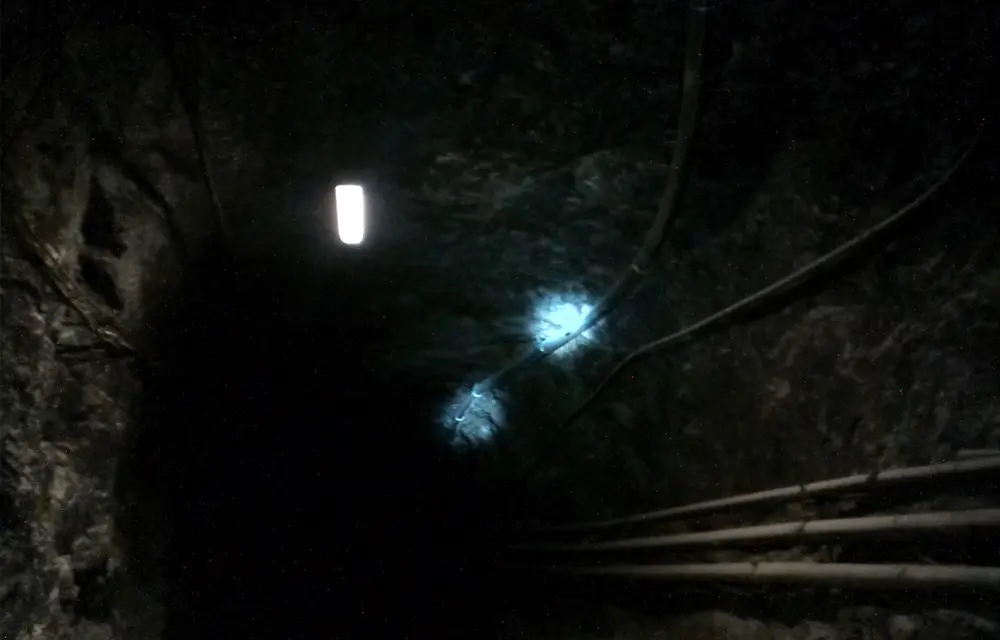

Water Drainage at an Underground Mine

Water Drainage From the Inside of an Underground Mine

Case Study Nº

31

Customer

El Peñón Yamana Gold, Meridian Mine

Chile

|

2016

Working Conditions

Extreme temperatures (-5° to 38°C).

Pexgol Pipes

Pexgol 160 mm Class 15 (SDR 11).

Application

Water drainage.

Lenght

600 m.

Categories

The Challenge

The water drainage from the inside of Meridian underground mine was processed through an HDPE 12 meter pipe that required 50 joints to be installed. The total installation time was 4 days, with no chance to minimize costs. Furthermore, the pump operated over it efficiency levels.

Pexgol Solution

A 600 meters Pexgol pipe 160 mm Class 15 was provided, in one section without joints. The Pexgol pipe was carried for 6 kilometers in 2 turns, which caused as a result 50% of time saved in the installation.

Due to the lower load losses, now the pump operates at its mayor efficiency level.

Related Case Studies

Water Drainage at an Underground Mine

El Peñón Yamana Gold, Meridian Mine

Chile

|

2016

Dewatering at an Open Cast Mine

Codelco, Ministro Hales Division

Chile

|

2016

From Steel to Pexgol: A Plumbing Upgrade for Tel Aviv’s Gordon Pool

Gordon Pool

Israel

|

2023