High Corrosion Resistance Against Brine

Pexgol Fittings for Brine Transportation at a Brazilian Chemical Company.

Case Study Nº

89

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Unipar Carbocloro is a Brazilian chemical company that operates in the soda and chlorine industry. At the outputs of the brine pumps, Carbocloro used to replace its piping components at least once every 6 months. They tried several materials and not one had performed successfully. The last ones were made of nickel and yet did not last more than six months, having leakages all around. The high corrosivity of the media was the main issue to be faced.

Pexgol Solution

Pexgol’s engineering team analyzed the whole situation, suggested a new design using Pexgol pipes and accessories and nowadays the output of the pump has worked non-stop (and with no signs of probable stops) for 9 months already.

The installation, despite the solution being formed by several parts, was easy and quick. Carbocloro’s team simply based the tasks on the plans providaded by the factory.

Related Case Studies

Addressing Drainage Challenges with Pexgol

|

Fast and Reliable Solution for Winemaking Processes

|

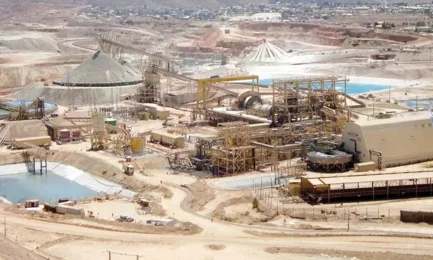

Water Drainage at an Open-Cast Mine

|

Water Transport Between Dams

|