Replacement of Metal Pipe with PE-X for Formation Water

Installation of a Pexgol Line for the Transport of Formation Water in an Oil Company.

Case Study Nº

116

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Enap Sipetrol Ecuador, is a branch of the Chilean state oil company Enap.

At their plant, they needed to transport formation water with 65,000-70,000 ppm of sodium chloride, which also had high salinity. This formation water has its origin at the outlet of a three-phase separator, up to a water storage tank. The existing metal pipes in the local market that are used for these processes corrode quickly and present leaks along the way. This situation made it necessary to apply chemical treatment to the pipes, with the cost that this represented, and even so, the treatment did not guarantee the integrity of the pipe.

Pexgol Solution

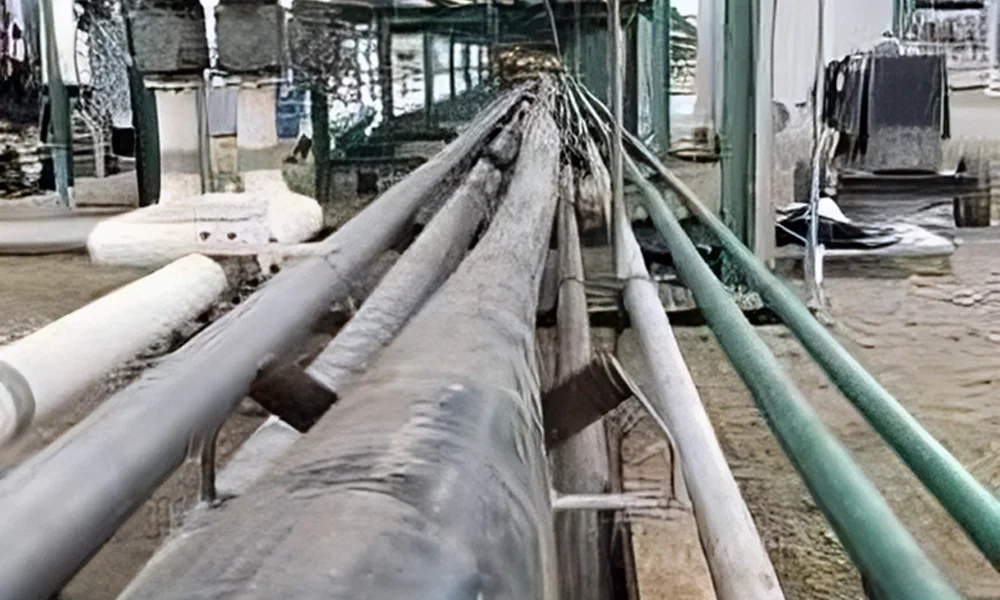

It was decided to use Pexgol pipe due to the working conditions that it can withstand for these applications and that also has a longer lifespan than the metal pipes usually installed, after the tests carried out, it was satisfactorily observed that it has not been any inconvenience, there are no leaks, no presence of corrosion and no solids adhered.

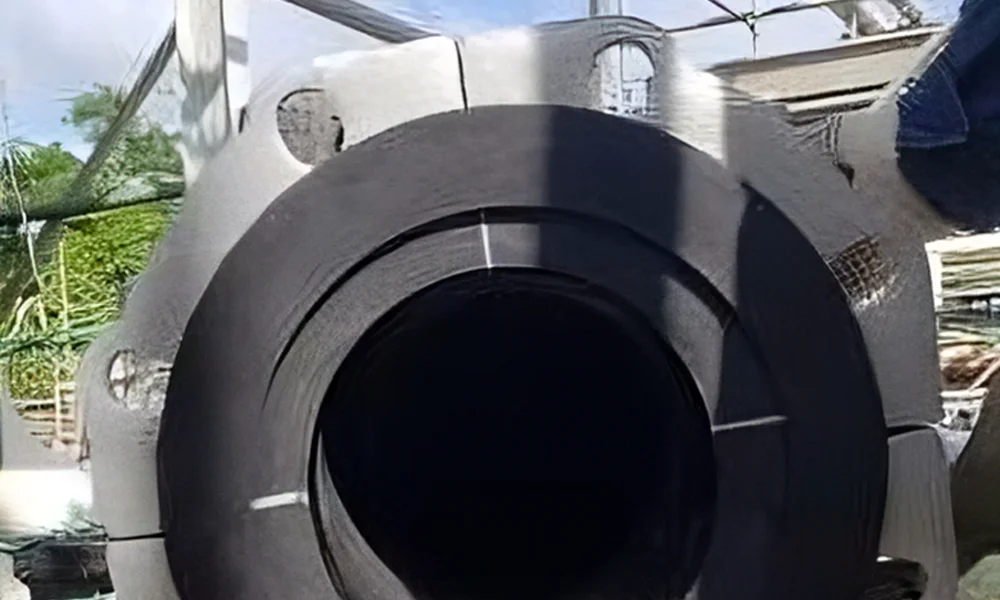

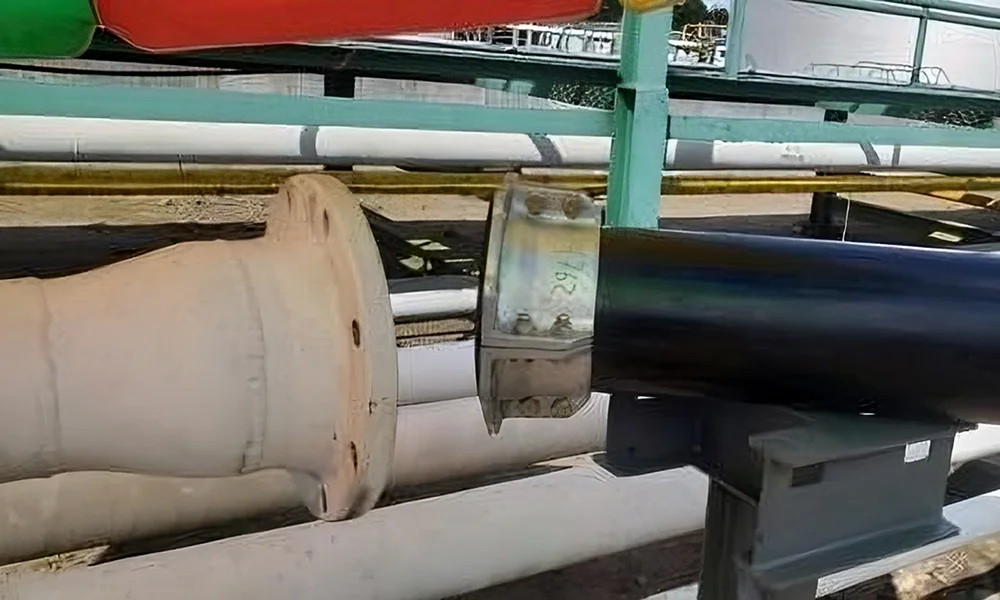

The installation of the 160 m of 225 mm diameter pipe was carried out with the collaboration of 12 people due to its dimensions and weight, in addition, locally manufactured “cradle” type supports were placed. For the assembly of the pipe, a horizontal unwinding machine was used, a crane truck, mobile roller stations for displacement, mechanical keys, torque meter and manual tools, 4 flanged couplings were installed for the terminations with their respective fixing clamps since that line it was installed in 2 sections.

Related Case Studies

Fewer Shutdowns, Greater Efficiency: Pexgol in the Salt Industry

|

Drainage System

|