Greater Efficiency and Safety in Leaching with Pexgol Pipes

Pexgol’s chemical resistance and flexibility outperform HDPE in demanding leach pad operations.

Case Study Nº

178

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Barrick Gold Corp., one of the world’s leading producers of gold and silver, operates under extreme environmental conditions at its Veladero project in Argentina. For its cyanide leaching pads, the company traditionally used 8” HDPE pipelines to transport cyanide solutions (pH 10) across wide temperature ranges, from -25°C to +35°C.

The biggest operational challenge stemmed from the irrigation method: after each leaching cycle, the pipelines were dragged manually to the next cell. This caused significant wear and mechanical fatigue, with HDPE pipes failing after just 4–5 uses. Their weight made handling difficult, increasing safety risks for personnel. Additionally, HDPE’s rigidity required a large number of fittings, particularly to navigate the 90×60-meter leaching pads, leading to higher costs and longer installation times.

Barrick sought a lighter, more flexible, and chemically resistant solution capable of withstanding extreme conditions and improving overall efficiency.

The Solution

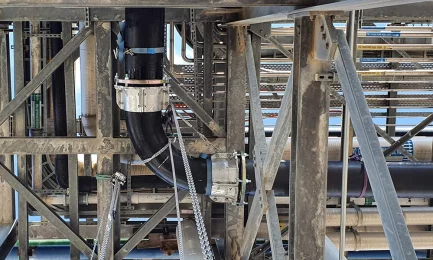

To address these issues, Barrick replaced the HDPE system with 300 meters of 110 mm Pexgol Class 10 pipe. Pexgol’s exceptional chemical resistance to cyanide solution and its ability to operate at sub-zero temperatures ensured optimal performance under extreme conditions.

The entire system was installed within a single workday, including staff training, on-site transport, and uncoiling in three stages. Thanks to Pexgol’s natural flexibility, bends and changes in direction were made without fittings, which reduced installation time and material costs. Its light weight allowed for easier and safer handling, even during pipe dragging across leach pads.

With fast deployment, high corrosion resistance, and easy roll transport, Pexgol enabled Barrick to improve operational efficiency. The pipe’s long lifespan—even under frequent dragging—made it a superior alternative to HDPE for cyanide leaching in mining applications.

Related Case Studies

Industrial Waste Water to MBR Treatment Facility

|

From Steel Struggles to Pexgol Progress

|