Syncrude & Pexgol: A Collaboration Set to Reshape Slurry Transport

Bridging the Gap between Durability and Functionality in Harsh Processing Environments.

Case Study Nº

148

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Syncrude Canada Ltd, a leader in the synthetic crude oil industry, faces a unique challenge in its production process. The extraction of raw oil called bitumen from oil sands is an intensive operation involving the transport of high-temperature slurry, which comprises water, sand, bitumen, and high oxygen content. Their existing pipeline, made from Schedule 80 carbon steel, was proving insufficient. This line was failing prematurely – in as little as 6 months, especially in high wear areas such as elbows and horizontal runs. The principal culprits were the the combination of the erosion and the corrosion from the high oxygen content that created the unique conditions accelerating the failure time for the carbon steel.

Pexgol Solution

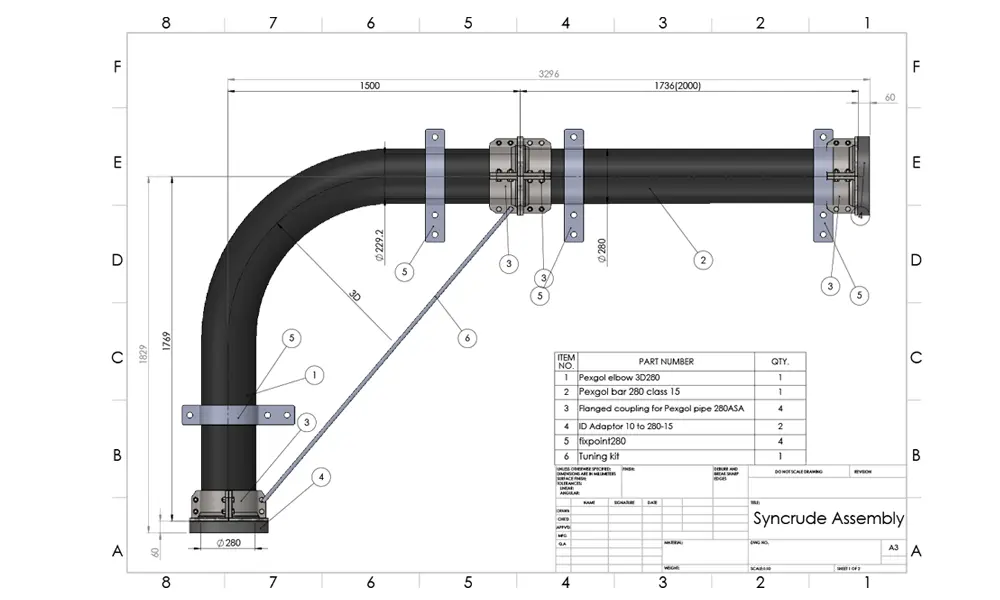

Pexgol, renowned for its high-grade PE-X piping systems, introduced its 280 mm, class 15 pipe to serve Syncrude’s rigorous requirements. The 10-meter pipeline was strategically designed to transport the high-temperature slurry under conditions of 82°C (179.6°F) and a pressure of 50 psi. The benefits of the Pexgol piping system — fast installation, high resistance to chemicals & corrosion, and exceptional durability — emerged as game-changers. With the added advantage of GP Flange Couplers and Pexgol Elbow fittings, the solution not only outlasted its carbon steel predecessor but also ensured a smoother, more efficient production process.

Related Case Studies

Hot Water Distribution for Solar Technology

|

Целлюлозно-бумажный комбинат

|

Success in Agricultural Desalination: Water Supply Challenges

|

Переработка минерального сырья — установка по переработке углекислого калия

|