Transforming Tailings Transport: The Pexgol Advantage

Pexgol’s proposal was clear - to provide a pipe that showcased superior wear resistance, estimated to be three times more durable than HDPE.

Case Study Nº

140

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

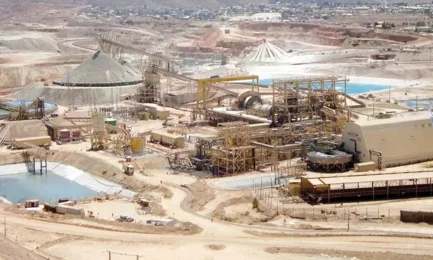

Minera Caserones, managed by Lundin Mining in Chile, previously utilized HDPE 14” PN20 SDR9 pipes for the transport of tailings sands. This application presented a significant issue; the HDPE pipes only had a lifespan of roughly 6 months, resulting in frequent replacements and potential operational downtimes. Working within a temperature range of 50°F to 77°F and depending primarily on gravitational pressure, the transportation of tailings sands, with a particle size median of d50: 150 [μm], at speeds varying between 3 to 10 [m/s] over different terrain slopes, necessitated a piping solution that was both durable and resistant to wear.

The Solution

Pexgol’s proposal was clear — to provide a pipe that showcased superior wear resistance, estimated to be three times more durable than HDPE. This objective was not only achieved but exceeded. The Pexgol 355 mm class 30 pipe, installed on December 20th, 2021, continues to operate efficiently, demonstrating the product’s significant longevity and the company’s commitment to excellence.

Notable Benefits for Minera Caserones:

- Rapid Installation: With the capacity to unroll lengthy segments, Pexgol pipes can be set up swiftly, reducing setup times.

- Extended Service Life: As evidenced by the ongoing operation of the Pexgol line, these pipes provide a durable solution, drastically cutting down on frequent replacements.

- Long Stretches: The ability to deploy extended segments of piping reduces the need for numerous connection points, enhancing the efficiency of fluid transport.

- High Wear Resistance: Tailored for abrasive environments like tailings transport, Pexgol pipes offer heightened resistance to wear, ensuring reliable and uninterrupted operations.

To date, the Pexgol pipeline remains in active operation, fulfilling and surpassing the objectives set at the beginning of the project. This not only testifies to the quality of Pexgol pipes but also highlights the company’s promise of delivering unmatched durability and operational efficiency.

Related Case Studies

Water Transport for Fire Network

|

Транспортировка химических веществ в морском порту

|

Efficiency and Durability in Handling Muddy Water

|