Aconcagua Energía Implements Pexgol Solutions for Efficiency and Savings

Transformation in the logistics of formation water.

Case Study Nº

158

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

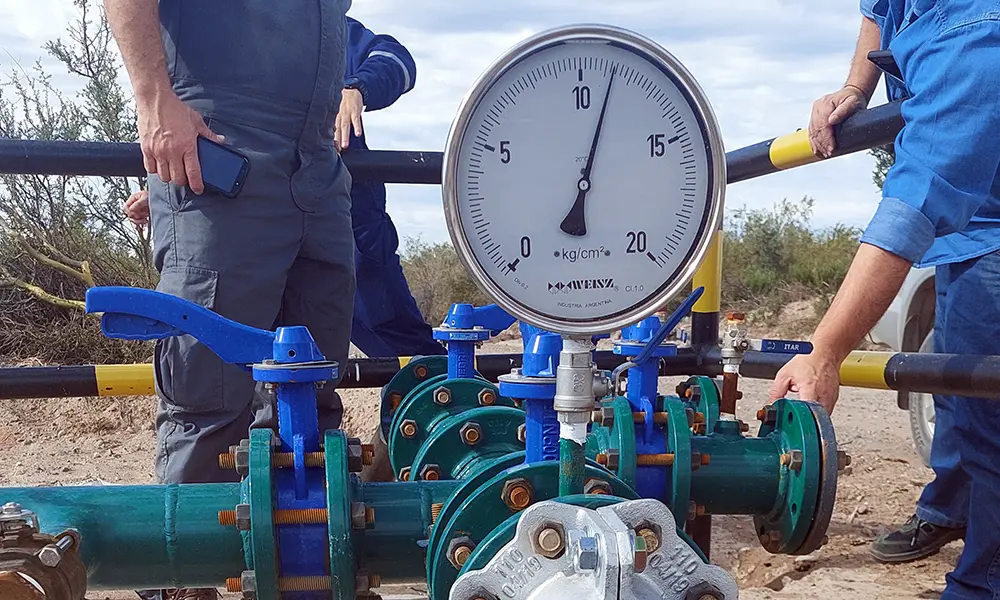

Aconcagua Energía, a prominent independent energy company in Argentina, faced significant challenges in transporting injection water, crucial for its oil operations. Traditionally, formation water was transported by trucks from the treatment plant to the elevated tanks, which not only represented a high operational cost but also involved risks associated with transport and logistical difficulties, especially during adverse weather conditions or certain times of the year. The need for a more efficient, safe, and economical solution was evident.

The Solution

In search of improving operational efficiency and reducing costs, Aconcagua Energía opted for the implementation of an innovative pipeline using 90 and 110 mm Pexgol for a total of 10,000 meters. The choice of Pexgol was due to its recognized advantages in terms of installation speed, material flexibility, lightness and ease of handling, as well as the ability to transport in rolls, which greatly simplified logistics on the ground.

The installation was carried out in stages, minimizing assembly times and optimizing the resources used. Mechanical double connectors and flanged couplings were used, facilitating a safe and efficient integration into the existing system.

The project not only eliminated the dependency on truck transportation but also brought tangible benefits in terms of operational costs and associated risks. The first phase of the installation included the assistance and training of Argpex in unrolling techniques and the use of mechanical connectors. For the later stages, the Aconcagua Energía team was able to carry out the installation autonomously, demonstrating the effectiveness and ease of implementation of the Pexgol system.

Related Case Studies

Efficient Open Pit Mine Drainage

|

Transporting Brine at High Pressure

|

Vertical Solution for Mine Dewatering in Fresnillo

|