Concentrated Copper Transportation

Lasta2 Filter Press Feed Lines

Case Study Nº

33

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

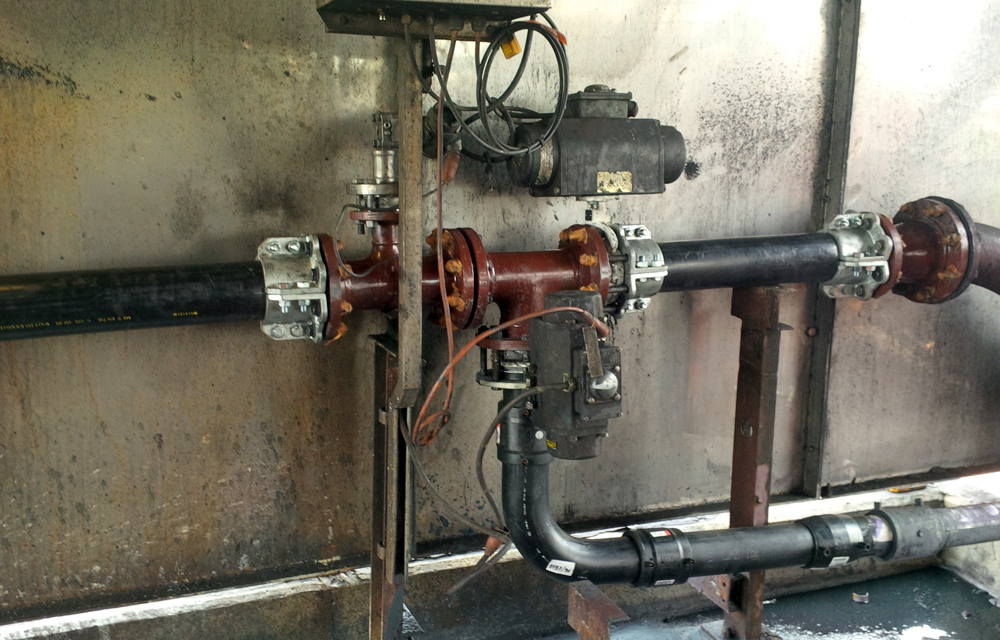

BHP used to transport concentrated copper, through a 6” rubber lined carbon steel (RLCS) and HDPE pipes that suffer from constant abrasion and corrosion.

From the maintenance point of view, repeating leaks were consuming too much time from the team, which could be allocated attending scheduled maintenance operations. So, they required a more resisting pipe material.

Pexgol Solution

Short sections of Pexgol pipe 180 mm, Class 15 with Pex-Lined Carbon Steel (PLCS) fittings were provided. The line installation took a day to layout and a day to assemble. The quick and secured flanged couplers allowed the team to work effectively in multiple locations of the line, without depending on a welding machine, or coordinating special safety zones. The line showed no leakage at start up.

Related Case Studies

Drainage System

|

Potable Water Supply on Harsh Terrain

|

Transport of Muddy Water in a Palm Oil Processing Plant

|