Water and Sulfide Transportation

Water transportation with sulfide and cobalt particles

Case Study Nº

22

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

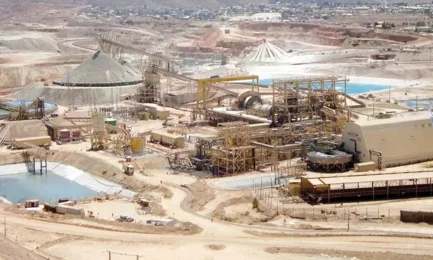

Moa Nickel transported water with nickel sulfide particles, this liquid formed a paste that was incrusted on the pipe walls and elbows, reducing it inside diameter. In order to repair the issue, they needed to stop the production plant, which required long maintenance time and as a consequence it decreased their productive capabilities.

Pexgol Solution

The former stainless steel pipe was replaced for a Pexgol pipe 250 mm, class 12. Even though the pipe had low thickness, it didn’t have problems such as wear nor incrustations. Likewise, due to its low roughness coefficient is lower than the titanium pipes, the head losses decreased and the pipe managed to work in a lower pressure with a greater flow.

Since the installation, the client didn’t spend on maintenance.

Related Case Studies

Fewer Shutdowns, Greater Efficiency: Pexgol in the Salt Industry

|

Fast and Reliable Solution for Winemaking Processes

|

Efficient Choice: PE-X Pipe for the Palm Industry

|