Addressing Drainage Challenges with Pexgol

Pexgol: Delivering Rapid, Reliable & Long-lasting Mining Drainage Solutions

Estudo de Caso Nº

149

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

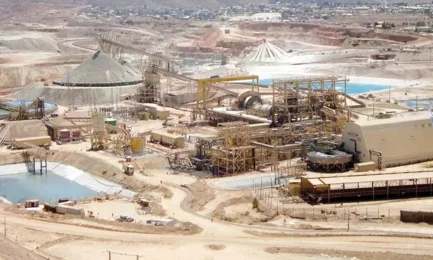

Minera Mexicana de Avino, with its vast gold and silver production operations near Durango, Mexico, faced a significant challenge. The company had been relying on HDPE piping for mine drainage. However, issues with pipe joints began to arise, which prompted the search for a more reliable and effective alternative. With a strategic focus on the acquisition of advanced exploration and mining properties, and a commitment to environmentally responsible operations, a durable and efficient drainage solution was critical.

Pexgol Solution

Recognizing the challenges, Pexgol provided a robust solution with its 480 meters of 6-inch SDR6 piping (2 coils) and 240 meters of 6-inch SDR11 piping (1 coil). These were employed across three separate lines, each measuring 240 meters (787.4 feet).

Pexgol’s unique attributes, such as rapid installation, long lifespan, and extended pipe lengths, directly addressed the challenges posed by the existing HDPE pipes.

The piping was installed in a ventilation duct where the ambient temperature ranges between 40° and 60°C (104° and 140°F), allowing the client to achieve substantial savings. Without installing the piping through the ventilation duct, they would have had to make a special borehole or install it via a ramp.

The installation was meticulously planned, especially since the existing path presented various challenges, including proximity to a fiber optic cable and the transit of machinery. With careful coordination, the installation was swiftly achieved, impressing the client with the speed and efficiency of the maneuver. The use of flanged couplings and load clamps ensured a secure and sturdy connection.

The feedback from Avino was overwhelmingly positive, expressing surprise and satisfaction at the rapidity of the maneuvering and installation process, reinforcing the benefits of choosing Pexgol.

Estudos de Caso Relacionados

Water Extraction from Wells

|

Transport of Muddy Water in a Palm Oil Processing Plant

|

Transportation of Alcohol for the Production of Rum and Brandy

|