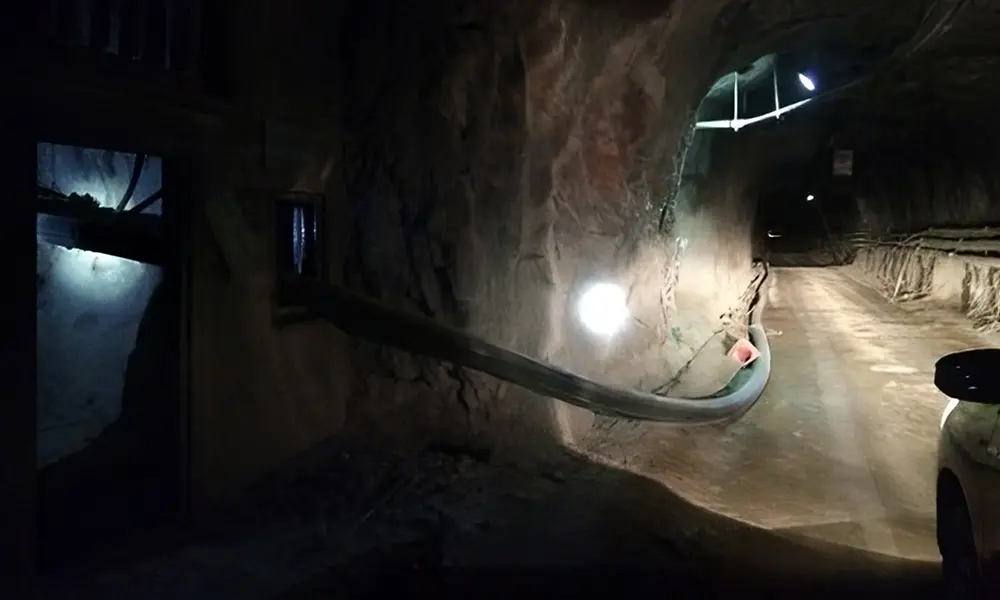

Vertical Drain in Underground Mine

Installation of Pexgol Pipes for Drainage of an Underground Mine

Estudo de Caso Nº

67

Cliente

Meridian Mine – Faena El Peñón

Chile

|

2018

Condições de Trabalho

Underground work

Solução Pexgol

Pexgol 160 mm (6”), Class 15 | Pexgol 160 mm (6”), Class 19 | Pexgol 200 mm (8”), Class 26.7

Aplicação

Mine Dewatering

Comprimento

800 m

Categorias

The Challenge

The Meridian mine (Faena El Peñón) required the installation of a line for the drainage of high-pressure water from the lower level of the mine, passing through the vertical ventilation chimney with a height of 150 meters, continuing through the interior of the mine until an outdoor pool.

Pexgol Solution

The client decided to install 800 m of Pexgol pipes in three di erent sizes:

Pexgol 160 mm (6”) Class 15, 160 mm (6”) Class 19 and 200 mm (8”) Class 26.7.

The installation was very simple:

- Lifting was carried out in the ventilation chimney.

- Mechanical connections were used that did not require special tools for installation.

- In the upper area the pipes were placed on supports provided by the mining company.

Pexgol was selected due to its capabilities:

- Possibility of supply in long lengths minimizing the connections to only 4.

- Ability to withstand the drag of more than 5 km from outside to the final assembly point inside the underground mine.

- Ability to withstand creep involved in vertical mounting of 150 meters.

Estudos de Caso Relacionados

Extraction of Underground Water

Doña Inés de Collahuasi SCM, Collahuasi Mine

Chile

|

2010

Free Chlorine Potable Water Supply

Rabin Medical Center

Israel

|

2020

Well Drainage at Mining Dam

CODELCO – El Teniente Mine

Chile

|

2019

Pexgol Ensures Water Supply at Mexican Combined-Cycle Power Plant

Kimex

Mexico

|

2025