Industrial Waste Water to MBR Treatment Facility

Replacement of HDPE Pipes For Pe-X to Transport Industrial Treated Water.

Case Study Nº

103

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

A semiconductor chip manufacturer company located in Israel, needed to replace an 10” HDPE line that transported industrial waste water to an MBR treatment facility.

Pexgol Solution

Having seen Pexgol’s experience in other projects in Israel and around the world, the client decided to install a 1000 meter Pexgol 400 mm, class 10 pipe.

The client was able to install the entire system in only 20 days since the pipes were supplied in sections of up to 57 m. Furthermore, Pexgol pipes do not require expansion loops since the pipe is able to withstand contractions and elongations without deformation.

Using Pexgol pipes allowed a faster installation time, helping reduce the total cost of the project.

It minimized potential failure points. Also reducing the cost of connections along the line.

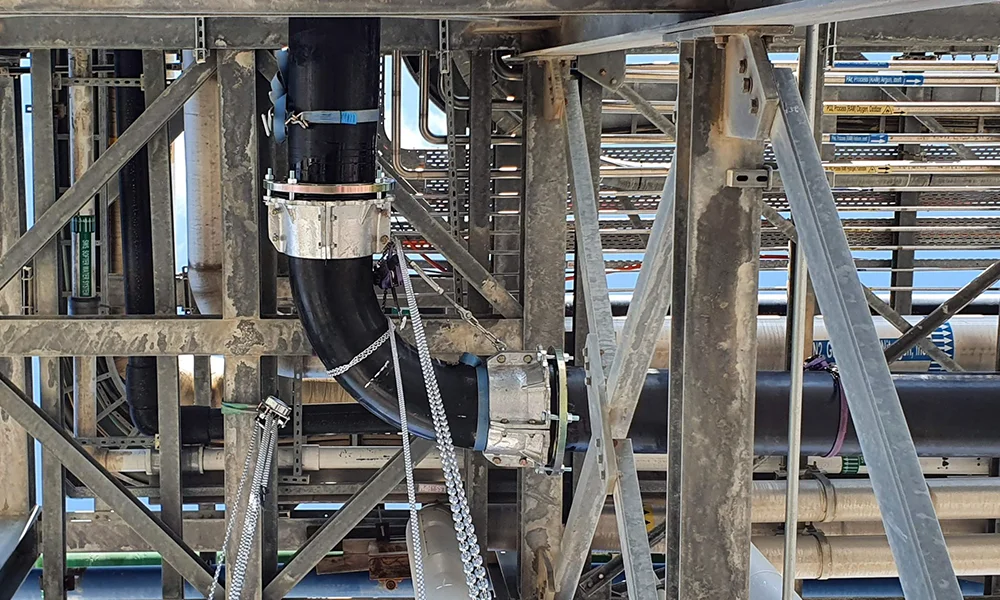

The installation was done on pipe-racks of 8.5 meter above ground. The connections were made using electrofusion welding and flanges. Additional fittings such as PE-X elbows and others were used.

Related Case Studies

Водопровод питьевой воды

|

Overcoming Corrosion Challenges in the Oil Industry

|

Aconcagua Energía Implements Pexgol Solutions for Efficiency and Savings

|

Replacement of Metal Pipe with PE-X for Formation Water

|