Efficient choice: PE-X pipe for the palm industry

Extractora Monterrey | Colombia | 2023

Characteristics

At the time of the study, Marine Farms were fattening Pacific Salmon or Coho with a 7 month fattening cycle.

About the cultivation center:

Variables to be measured

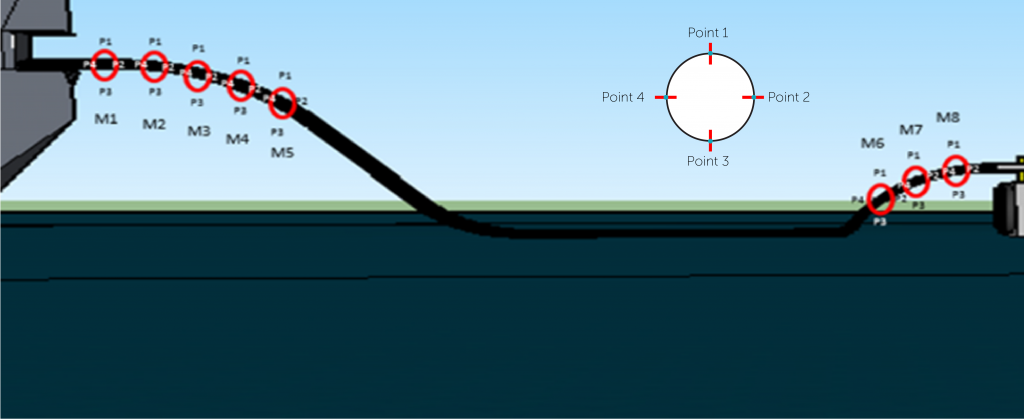

Measuring points

The measurement was made at the major inflection points, where by historical background and by the turbulence that occurs in these areas, the pipes are more affected by the abrasion of the food.

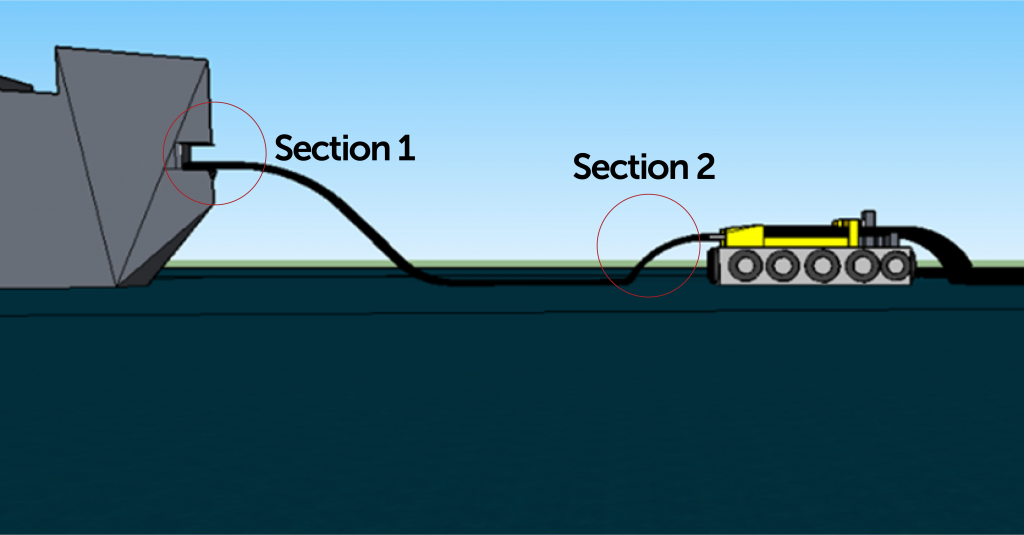

Sections for the study of thicknesses

Measuring points for piping (ultrasound)

Results

The average rates of wear give an expected result for Pexgol piping compared with HDPE piping under the same operating conditions. Average values of 3.26 – 4.69 mm / month for HDPE versus 0.0 – 0.26 mm / month for Pexgol were obtained. It is concluded that the operational life of the HDPE is projected at only 2.6 – 3 months under the feed rates assessed as average. Under the same conditions the Pexgol is projected to last nearly 18 times as long, that is 4.5 years (54 months).

Comparative table of wear measurement results:

| Measuring points (mm) | HDPE | Pexgol |

|---|---|---|

| P1 | 4.69 | 0.26 |

| P2 | 3.73 | 0.02 |

| P3 | 3.26 | 0.00 |

| P4 | 3.63 | 0.14 |

Economic benefits

To analyze the economic benefit offered by the Pexgol pipeline for the salmon farming centers, considering only its longer lifespan due to greater resistance to wear, the total meters of feeding pipes of the cultivation center, its cost per meter and the replacement cost.

| HDPE | Pexgol | |

|---|---|---|

| Meters | 1.440 | 1.440 |

| Value USD/ m | 4.2 | 10.4 |

| Total Pipe Cost | $6,048 | $14,976 |

| Replenishment cost 1st cycle | $6,048 | – |

| Replenishment cost 2nd cycle | $6,048 | – |

| Total Cost | $18,144 | $14,976 |

To analyze the economic benefit offered by the Pexgol pipe due to the lower loss of fines and brokens, due to the fact that the Pexgol pipe has a roughness coefficient much lower than that of a conventional PE pipe, samples were taken from the Cellar, Dispenser and the output of the Selector.

This test was carried out in conjunction with the laboratory owned by the food supplier in Puerto Montt, through sieves required and recommended by the laboratory technicians. The measurements resulted in an economic saving of 63% only for this concept.

HDPE

| Cellar | Dispenser | Selector | |

|---|---|---|---|

| Percentage of fines and broken | 0.17% | 1.74% | 1.41% |

| Food used per cycle (kg) | 1,720,000 | 1,720,000 | 1,720,000 |

| Amount of food loss (kg) | 3,007 | 29.957 | 24.257 |

| Salmon feed cost (USD / kg) | 1.45 | 1.45 | 1.45 |

| Loss in US dollars | US$4,360 | US$43,438 | US$35,173 |

Pexgol

| Cellar | Dispenser | Selector | |

|---|---|---|---|

| Percentage of fines and broken | 0.14% | 1.08% | 0.52% |

| Food used per cycle (kg) | 1,720,000 | 1,720,000 | 1,720,000 |

| Amount of food loss (kg) | 2,386 | 18.616 | 8.946 |

| Salmon feed cost (USD / kg) | 1.45 | 1.45 | 1.45 |

| Loss in US dollars | US$3,459 | US$26,993 | US$12,971 |

Savings

| Savings | US$900 | US$16,445 | US$22,202 |

| Percentage of Saving | 21% | 38% | 63% |

Client

Marine Farms

Chile | 2017

Pipes used:

Pexgol 90 mm (6 mm wall thickness)

HDPE 90 mm (10 mm wall thickness)

Application:

Fish feeding

Certification:

Study certified by the Universidad Austral de Chile, (Puerto Montt) through a Thesis.