Transport of Lime Slurry

Transport Of Lime Slurry At 100°C

Case Study Nº

28

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

The client needed to transport lime slurry, which is highly fouling due to the high temperatures and the liquid consistency. The lime slurry was transported at 100°C, damaging all metals and plastics that were not resistant enough. The fouling caused a considerable diminution on the inside diameter of the former pipe, sometimes even closing it completely. Previously the client used to work with a rubber hose, but due to the extreme conditions, and the lack of a flat inside surface, it wasn’t enough to prevent the accumulation.

Pexgol Solution

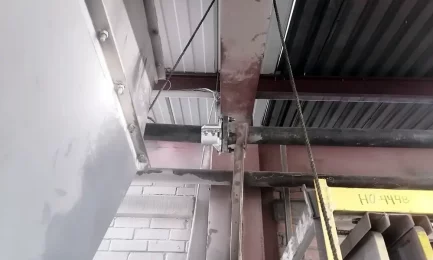

Golan provided 50 meters of Pexgol 90 mm pipe (3” – SDR 7.4). The installation was easy due to the one section pipe, that didn’t require joints. The natural curve radio was utilized to pass all the obstacles during the installation. Pexgol pipes proved to be the best solution, thanks to it’s high resistant to abrasion, corrosion, encrustation and resistance to high temperatures.

The client saved costs; formerly the rubber hose cost 6 times more than Pexgol. In the other hand, the MTBF was just two month.

Since the Pexgol pipe installation no maintenance has been required, not even plant stops.

Related Case Studies

Improving efficiency in steel foundry with Pexgol

|