Corrosive Material Transportation

Transport of high corrosive material from the thickeners to the neutralization plant

Case Study Nº

23

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

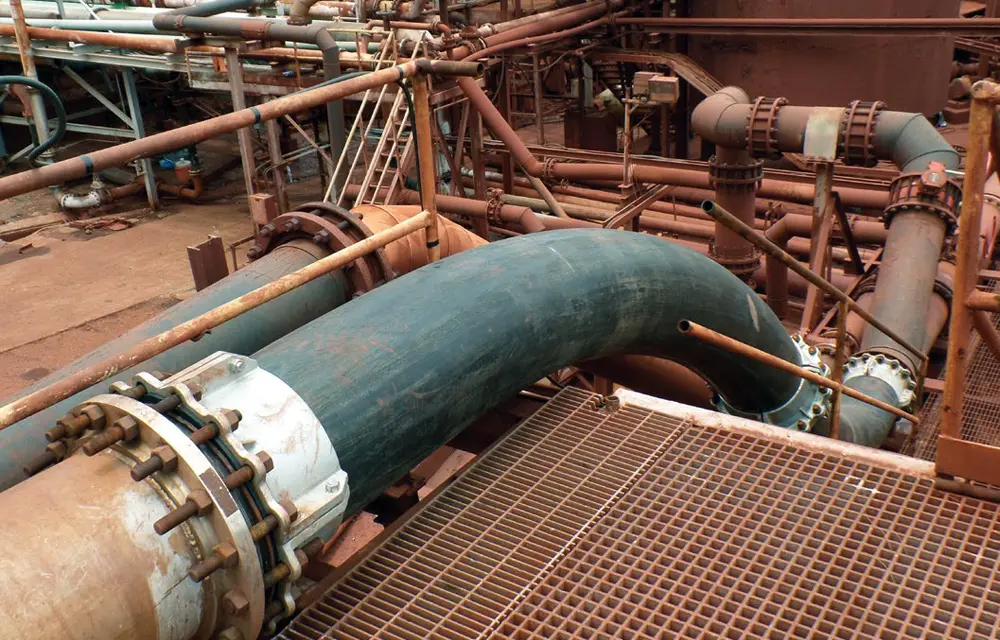

Moa Nickel required to transport high corrosive material from the thickeners to the neutralization plant tanks. Originally, they used to do it through a 18 and 16 inches carbon steel line (A53, Gr.B, Sch10), with welded joints and 1/4” rubber lined. The pipe consisted in short pipe sections, 6 meters long each one, approximately 150 meters total length. It was used until it was practically destroyed as a consequence of the corrosion and wear. The engineering team decided that it needed to be replaced before it could affect the production.

Pexgol Solution

Golan presented a quick-to-install solution for the complete substitution of the line. The design included standard and special Pexgol fittings, elbows, Tee instruments and more than 150 meters of pipe. The Pexgol pipe was installed in the same spot as the former carbon steel pipe, improving the supports.

The former carbon steel pipe was 50% more expensive than Pexgol, which also was more convenient and easy to install, saving time and money for its installation.

| Pipe Type | Pexgol Cost vs Others | Pexgol Total Investment Costs vs Others |

|---|---|---|

| Rubbed steel A53 Gr, B Sch. 20 | 1:1.4 | 1:2 |

| Stainless steel 316L, Sch. 20 | 1:2 | 1:3 |

| Titanium B862, Gr.2, 3 mm thk | 1:2.3 | 1:3.2 |

| Polypropylene PP-H, SDR 17 | 1:3.8 | 1:4.2 |

Related Case Studies

Compressed Air System

|

From carbon steel to Pexgol: A victory against corrosion

|