Goodbye Asbestos: Pexgol Modernizes Thermal Water Network

850 Meters of Pipe Replaced in Less Than 24 Hours, Without Affecting Residents.

Case Study Nº

180

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Raquet Club Lake Chapala, a tennis club located in San Juan Cosalá (Mexico), had a thermal water distribution network built with 10” asbestos cement pipes installed several decades ago. Although this material was considered durable at the time, it is now recognized as hazardous: asbestos fibers can be released as pipes deteriorate, posing a serious health risk to residents.

The community faced a dilemma. Replacing the existing line with conventional solutions would involve prolonged interruptions to the potable water supply— an unacceptable impact for users. Additionally, the available alternatives could not guarantee sufficient resistance to the network’s demanding conditions: high temperature (87°C), pressure of 9.9 bar, and aggressive chemical composition (bicarbonates, chlorides, sulfates, calcium, magnesium, sodium).

Traditional options also required extensive excavation to remove the old pipes, significantly increasing costs and extending the project timeline. The structural deterioration of asbestos cement, combined with health and operational risks, made an innovative, efficient, and safe solution urgently necessary.

The Solution

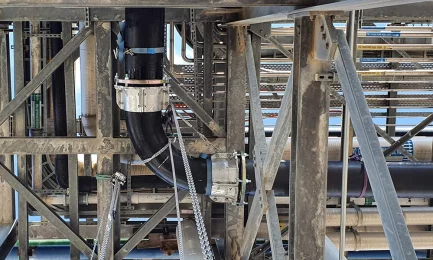

The choice of Pexgol pipes for this renovation was key to overcoming all project challenges. A total of 850 linear meters were installed in different pressure classes (SDR 7.3, SDR 11, and SDR 15) in just one working day, meeting the commitment to keep water supply interruptions under 24 hours.

How was this achieved? By using the existing asbestos pipe as a guiding duct, the new Pexgol line was pulled through the entire route with a steel cable, eliminating the need for excavations. Thanks to its abrasion resistance and high flexibility, Pexgol withstood the pulling process without compromising its integrity. In addition, its ultra-smooth inner surface (roughness 0.0006 mm) allowed maintaining the original flow rate despite the pipe’s smaller internal diameter, optimizing hydraulic performance.

The installation was carried out using flanged couplings, without welding or complex works. Although the contractor had no prior experience with this system, Pexgol’s technical team provided full support: maneuver selection, staff training, and detailed planning. The result was a fast, clean, and safe implementation—without causing inconvenience to residents.

Related Case Studies

Water Transport Between Dams

|

Industrial Waste Water to MBR Treatment Facility

|

Fewer Shutdowns, Greater Efficiency: Pexgol in the Salt Industry

|