Optimization of Lithium Brine Transportation

Moving from PVC to Pexgol: Ensuring Efficiency in Lithium Production

Case Study Nº

143

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Puna Mining S.A., a pioneer in high-quality battery-grade lithium carbonate production (99.5% purity) in Argentina, faced operational challenges with its brine transportation system. Founded in 2017 by Pablo Alurralde and later forming a joint venture with Argosy Minerals Ltd., the company was committed to utilizing cutting-edge technology in its production processes. However, their existing PVC piping presented significant limitations, requiring constant maintenance, frequent pipe replacements, and struggling with ongoing crystallization issues, which directly affected efficiency and increased operational costs.

Pexgol Solution

Pexgol stepped in with a tailored solution to address Puna Mining’s challenges.

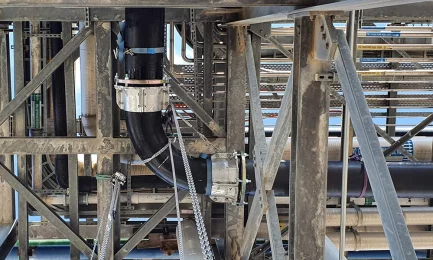

The introduction of Pexgol pipes of 6, 2, and 5 inches over a 2-kilometer stretch was designed to meet the specific demands of raw brine transportation.

The complete installation was accomplished in just three days, highlighting the ease and efficiency of Pexgol pipes.

ArgPex provided on-site training to ensure a smooth and optimized installation process.

Benefits of Switching to Pexgol

By adopting Pexgol pipes, the following advantages were realized:

- Rapid installation

- High chemical and corrosion resistance

- Material flexibility

- Long lifespan

- Reduced thermal conductivity

- Lightweight pipes

- Availability in long rolls for easier handling and installation

Related Case Studies

Industrial Waste Water to MBR Treatment Facility

|

Installation of Water Well in Reduced Space

|

Evolving Mine Operations with Pexgol Piping

|