Water Transport in Complex Terrain

Transportation of River Water in Rough Terrain

Case Study Nº

60

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

At the Cuajone mine (Southern Copper) they needed to install a new line at a height difference of 400 meters that presented an important construction challenge. This line had to transport pumped river water to a tank.

The line had to cross two slopes and an abrupt terrain of great complexity with the presence of large rocks, without access roads and adverse climatic conditions to carry out any work.

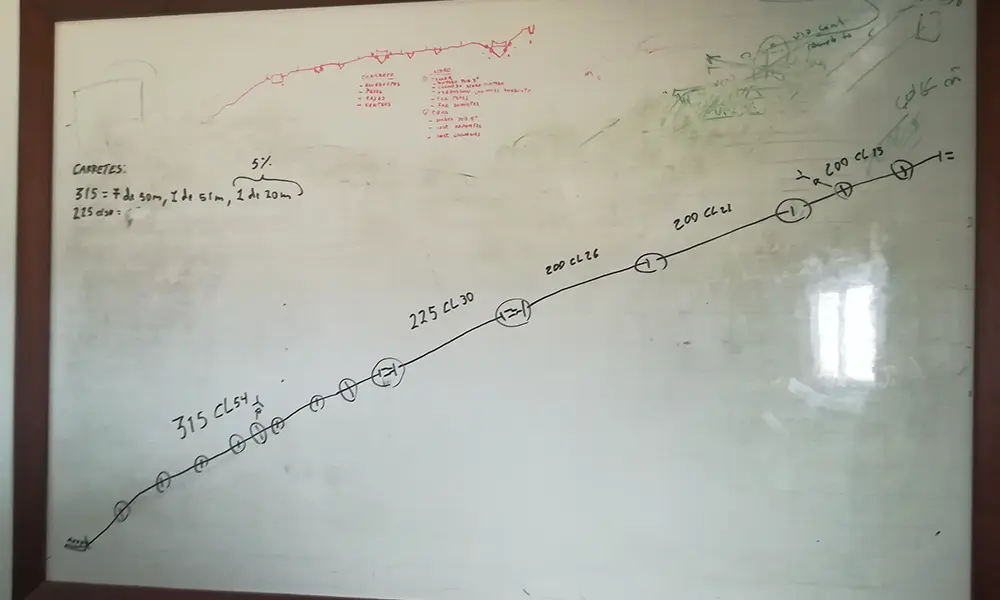

The design pressure in the area of highest pressure was 54 bar.

Pexgol Solution

Our technical team after studying the project and visiting the field, decided to use a special pipe in class 54 for the area of higher pressure and for the remaining sections classes 30, 26, 21, 15 respectively.

All the pipe sections were delivered in a long-length coil format, which allowed designing an installation plan with greater productivity compared to other material alternatives such as carbon steel.

The solution also included the design of special connections considering that during the pick-up, the couplings would impact with all kinds of obstacles (rocks, bushes, cactus, etc). The sections were gradually jointed on the upper platform and then drag and drop hundreds of meters. The complete installation of the line (including the welds and mechanical joints) took approximately a quarter of the time it would have taken to have done it in carbon steel, allowing significant savings in manpower and machine hours.

Cutting tools and other tools were used for welding by electrofusion and other conventional accesories were used for the tightening of the special couplers. A total of 14 unions were executed.

Related Case Studies

Fish Oil Transport at 36°C / 96.8°F

|

Vertical Dewatering

|