Fish Oil Transport at 36°C / 96.8°F

Installation of Pexgol Pipes in a Fish Processing Plant.

Estudo de Caso Nº

97

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

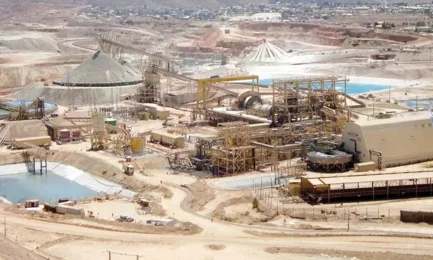

Guaymas Protein, a Mexican company dedicated to the production and commercialization of fishmeal, oil and soluble fish concentrate worldwide, had an underground carbon steel pipeline, where they transported fish oil from one container to another.

These pipes rusted in a very short period of time due to the salinity, humidity and conditions where the plant is located, resulting in the contamination of the transported fluid.

Given the circumstances, Guaymas contemplated reviewing three possible options for the replacement of this line. The piping options were: carbon steel, PE-X or stainless steel.

Pexgol Solution

Once the three aforementioned piping options were analyzed, Pexgol was chosen due to its high resistance to corrosive environments, impact resistance, and supply in long lengths.

Installation was quick and easy, in a single 150-meter section which was installed in approximately 4 hours, only 2 joints were made at the ends.

Estudos de Caso Relacionados

Open Cast Mine Dewatering

|

Extraction of Underground Water

|

Installation of Water Well in Reduced Space

|

Water Extraction from Wells

|

Alumina Plant: Ore Slurry Transportation

|