Efficient Choice: PE-X Pipe for the Palm Industry

Pexgol pipe was selected for the Assembly of a Muddy Water Transport Line for a Palm Oil Processing Company.

Estudo de Caso Nº

120

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

The agroindustrial Colombian company Extractora Monterrey S A S is dedicated to the cultivation and processing of palm fruit, for the extraction of crude oil, palm kernel oil and palm kernel cake. It required the installation of a new line to transport muddy water to the oxidation ponds. From the Florentine passing the main road and the plantation, the excavation and installation of the pipe would be carried out in the crop, between palm trees without causing damage to the plants and the irrigation pipe.

Pexgol Solution

In this case, PE-X pipes were chosen because they are cheaper compared to the installation of stainless steel pipes.

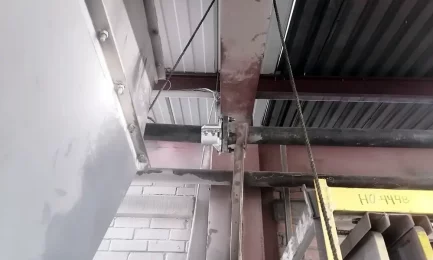

Another factor that influenced the decision to use PE-X pipes was its ease of installation. The installation process was quick and easy, allowing the 200 meters of pipe to be laid in just 4 hours, using only two 15/16 wrenches, a level and a GP mechanical union.

In addition, PE-X pipes have fewer joints, which reduces the risk of leaks and therefore increases efficiency in transporting palm oil.

Finally, the recommendation of another client who had used PE-X pipes in other projects with good results also influenced the decision to use this type of pipe in the installation.

In summary, the choice of PE-X pipes in the transport of slurry water is due to its lower cost compared to stainless steel pipes, its ease of installation, fewer joints, recommendation from other clients and the speed of delivery. placement, which reduced the time and number of personnel required for installation.

Estudos de Caso Relacionados

Pexgol’s Solution for CFE: A Leap in Durability and Efficiency

|

Recovered Water Transportation

|

Water Drainage at an Open-Cast Mine

|

Mine Dewatering at Low Temperature

|

Improving efficiency in steel foundry with Pexgol

|