Implementation of Pexgol Pipelines for the Transport of Muddy Water

Adapting to the demands of the process: how Pexgol solves the problems of corrosion and abrasion in the extraction of palm oil.

Estudo de Caso Nº

125

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Industrial Aceitera De Casanare S.A. is a leading company in palm oil extraction in the Casanare region, Colombia. In their production process, the company faced a significant challenge: replacing several sections of the line leading from the plant to the oxidation lagoons due to the high wear and corrosion of the existing piping.

The piping in question transported muddy water (POME), with a high organic load and temperatures between 90ºC and 100ºC. The flow rate was 40 m3/h, which represented a significant challenge for the durability of conventional piping. Industrial Aceitera De Casanare needed a solution that would guarantee the efficiency and continuity of its operations, reducing maintenance costs and downtime.

Pexgol Solution

The company decided to implement Pexgol piping, known for its high resistance and success in the palm oil industry. Pexgol is especially resistant to high temperatures, corrosion, and abrasion, making it the ideal solution for Industrial Aceitera De Casanare’s specific needs.

They used 100 meters of 90mm Class 15 Pexgol piping to replace the affected sections of piping. Adopting Pexgol allowed the company to reduce plant shutdowns, costs, and maintenance time, resulting in increased efficiency and profitability.

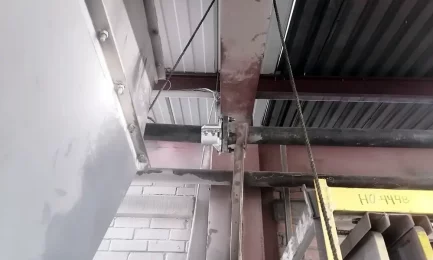

The installation of 100 meters of piping was done in sections to progressively replace the worn-out piping. Twelve GP mechanical couplings were used.

The ultimate goal of this pilot project is to demonstrate the viability of investing in Pexgol piping, allowing Industrial Aceitera De Casanare to expand its use to other lines in its infrastructure. The successful implementation of Pexgol in this case study is a testament to the quality, durability, and efficiency that this product offers to the palm oil industry.

Estudos de Caso Relacionados

Water Drainage at an Underground Mine

|

Improving efficiency in steel foundry with Pexgol

|

Water Transportation on a Mining Road

|

Transport of Silica Arena: HDPE vs Pexgol

|