Pexgol Enhances Lithium Brine Well Testing Manifolds

Corrosion-resistant, lightweight piping for challenging mining environment.

Estudo de Caso Nº

167

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Gaana Servicios Mineros, a leading company in Argentina, faced a significant challenge in managing its manifolds used for lithium brine well testing. These manifolds, consisting of pipe assemblies, valves, and sensors located at the wellhead, are crucial for directing flow to control ponds and determining the well’s potential and other critical characteristics.

Traditionally, the manifolds were constructed from carbon steel, a material that, while robust, posed several drawbacks. Carbon steel suffered from corrosion and scaling due to constant contact with lithium brine. Additionally, its heavy weight complicated the transport and assembly of the manifolds, especially in cases where tests lasted only a few days, requiring frequent relocation between different wells. This necessitated the use of a crane truck and additional logistics, increasing operational costs.

The Solution

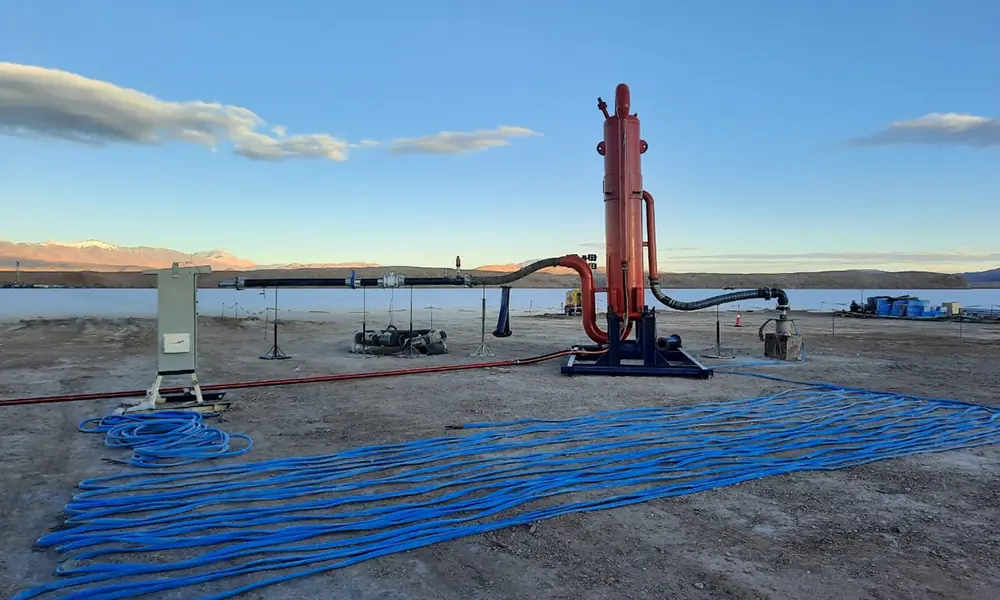

To overcome these challenges, Gaana Servicios Mineros chose to replace the carbon steel manifolds with 110 mm and 160 mm, class 10 Pexgol pipes. Pexgol stood out as the ideal solution due to its high resistance to chemicals and corrosion, lightweight and easy handling, and long service life.

The installation of the new Pexgol manifold was notably fast and efficient, completed in under 2 hours. The process involved assembling the three main parts of the manifold along with accessories such as flow meters, pressure gauges, and valves, using GP flanged joints and straight PEX pipe sections, along with Stub Ends and loose flanges.

The use of Pexgol pipes in Gaana Servicios Mineros’ manifolds not only eliminated issues of corrosion and scaling but also significantly reduced weight and costs.Compared to a stainless-steel manifold, the company achieved a 39% cost reduction and a 46% weight reduction for the 110 mm pipes. These improvements not only facilitated easier transport and installation but also optimized the company’s overall operational efficiency.

Estudos de Caso Relacionados

Water Drainage at an Underground Mine

|

Compressed Air Transportation

|

Mineral Processing – Potash Processing Plant

|