Efficiency and Durability in Handling Muddy Water

Case Study: Pexgol’s Solution at the Palm Oil Plant.

Case Study Nº

163

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

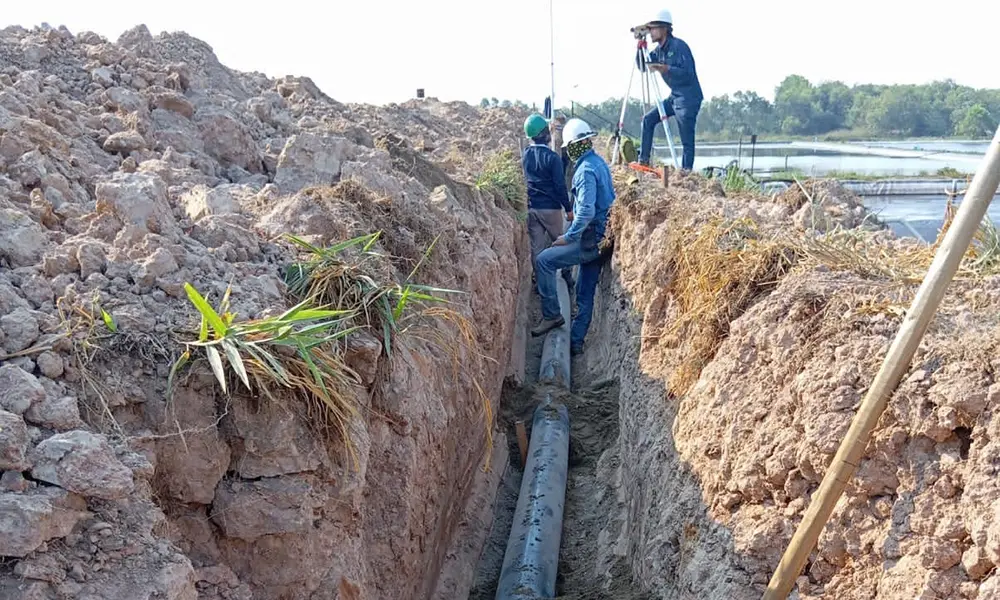

Industrial Aceitera del Casanare S.A., a palm oil processing plant in Colombia, faced the need to install a new line for the transportation of POME (Palm Oil Mill Effluent) from the plant to the oxidation ponds. This fluid, with a high organic load and operating at temperatures between 90°C and 100°C, posed a significant challenge due to its corrosive and abrasive nature. In 2022, the company had already tested a 100-meter section of Pexgol pipe, achieving excellent results in terms of resistance and durability.

The Solution

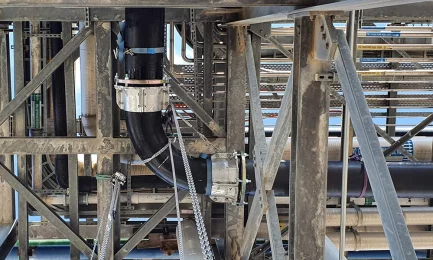

To address this challenge, Industrial Aceitera del Casanare decided to use 200 mm, class 15 Pexgol pipes over a length of 270 meters. The choice of Pexgol was based on its great resistance to high temperatures, corrosion, and abrasion, promising a durable and reliable solution for the transportation of POME. The implementation of Pexgol allowed the

plant to reduce downtime, as well as the costs and times associated with maintenance.

The installation of the 270 meters of Pexgol pipe was carried out efficiently using only two GP mechanical joints. This process did not require special tools, which further simplified the installation and minimized disruptions to plant operations. Since the implementation of the new line, Industrial Aceitera del Casanare has experienced a significant improvement in operational efficiency, with a notable reduction in maintenance times and plant downtime.

The success of this project highlights Pexgol’s ability to handle extreme operating conditions and highly corrosive and abrasive fluids.

Related Case Studies

Compressed Air Transportation

|

Industrial Waste Water to MBR Treatment Facility

|

Dewatering Through Shafts

|

Recovered Water Transportation

|