Overcoming Installation Hurdles and Enhancing Operational Efficiency

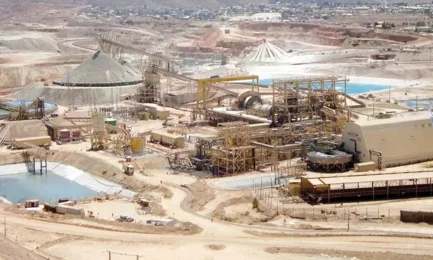

Streamlining Mine Dewatering and Water Transportation with Pexgol Pipes at Cerro Negro Mine.

Estudo de Caso Nº

134

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Newmont Corporation, an American gold mining company and the world’s largest gold mining corporation, owns mines in various locations worldwide, including their Cerro Negro mine located in Santa Cruz, Argentina. The mining process requires robust and efficient infrastructure, and for Newmont, the pipeline system was presenting a significant challenge.

The mine needed to add dewatering lines, they previously used High-Density Polyethylene (HDPE) for their service lines, which resulted in logistical and operational problems. HDPE pipes are typically produced in lengths of 12 meters, necessitating a high degree of manipulation during installation. This was particularly challenging in a mining environment, where efficiency and safety are paramount.

Furthermore, the rigid nature of HDPE piping limited its application in environments with complex terrain and demanding conditions, typical of mining operations.

Pexgol Solution

Recognizing the limitations of HDPE and the need for a superior solution, Newmont Corporation turned to Pexgol – a PE-X pipe renowned for its durability, flexibility, and ease of installation.

Pexgol 160mm class 30, 110mm class 24, and 110mm class 30 pipes were used, extending over 1100 meters for underground mine dewatering and water transportation. The pipes were installed using double mechanical connectors and Victaulic fittings, ensuring a secure and leak-free connection.

The installation process was significantly streamlined due to the advantageous properties of Pexgol. An impressive 500 meters of pipeline were installed in just 5 hours, a testament to the efficiency of the product. Pexgol’s long lengths and lightweight properties allowed the pipe to be quickly deployed down a ramp and subsequently hung in place.

Estudos de Caso Relacionados

Water Extraction from Wells

|

Recovered Water Transportation

|

From carbon steel to Pexgol: A victory against corrosion

|