Pulp & Paper Mill

Hot Caustic Line Replacement in Paper Mill

Estudo de Caso Nº

51

Cliente

Svetlogorskiy Mill

Russia

|

2015

Condições de Trabalho

Non-pressure, high temperature and scrubber water

Solução Pexgol

Pexgol 160 mm Class 15

Aplicação

Alkali transportation in caustic and regeneration workshop

Comprimento

13 m

Categorias

The Challenge

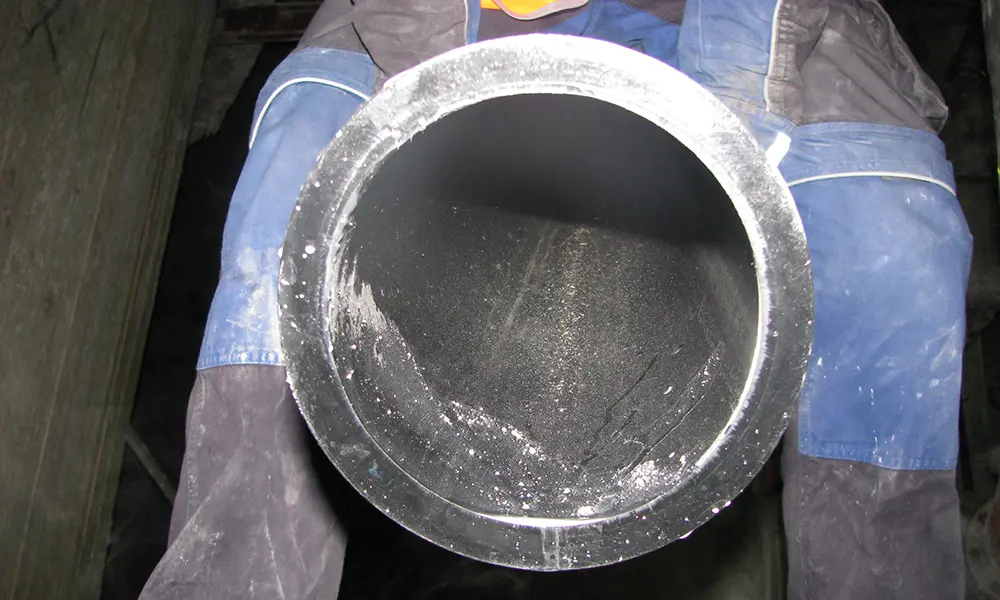

At Svetlogorskiy Mill Paper Plant they needed to repair their stainless steel pipes a few times a year, since they were transporting alkali at very high temperature.

The main challenge for the line was the sedimentation issues.

Pexgol Solution

The client decided to replace the stainless steel pipes with Pexgol pipes. Thanks to it smooth inner surface, sedimentation is not a problem and as a consequence requires less maintenance.

The line has been installed since 2015 and it stills shows amazing results.

Estudos de Caso Relacionados

Water Drainage in Underground Mine

NEMISA Mine

Mexico

|

2018