Reliable Solution for Deep Wells in Corrosive Environments

Química del Rey replaced a corroded steel column with a Pexgol line, achieving a faster, safer, and more durable installation.

Estudo de Caso Nº

184

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Química del Rey, a producer of inorganic chemicals belonging to the Peñoles Group and located in the Laguna del Rey region in Coahuila, faced several challenges in the operation of its wells.

The existing column, made of stainless steel, suffered severe deterioration caused by the combination of hard water, high temperatures (40°C), and high levels of calcium and magnesium salts.

These conditions promoted intense corrosion that compromised the structural integrity of the line and drastically reduced its useful life. The wear of the stainless-steel column increased the risk of pump loss, which is why the company relied on the installation of a steel cable as an additional measure to prevent equipment failure.

Constant maintenance and the associated risks had become an operational and economic issue that required a more resistant and long-lasting alternative.

The Solution

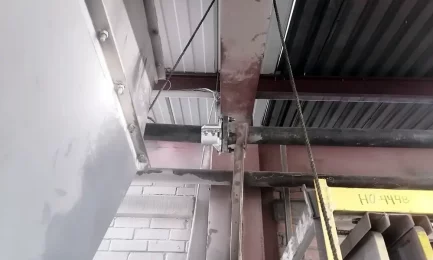

To solve this issue, the company decided to install a well column using Pexgol 160 mm Class 15 pipe, in a 120-meter section inside the well. Pexgol was selected due to its high resistance to corrosion and aggressive agents, as well as the possibility of using coils of great length, reducing the number of joints and potential failure points.

The installation was completed in a single morning, thanks to the ease of handling and flexibility of the pipe. The process consisted of inserting the line, placing the pump, and assembling all components as the pipe was lowered into the well. A reducer with NPT threads was installed to enable connection to the stainless-steel pump. No specialized equipment was required. The ease of installation allowed the electric cable to be securely tied every two meters along the entire length, ensuring optimal handling.

Thanks to Pexgol’s specialized technical support, the team at Química del Rey executed the installation without any issues, even though this was their first time working on this type of project. The result was a fully corrosion-free, fast, safe installation that clearly demonstrated the effectiveness of the Pexgol solution and paved the way for future implementations within the company.

Estudos de Caso Relacionados

From carbon steel to Pexgol: A victory against corrosion

|

Water Transportation on a Mining Road

|

Improving efficiency in steel foundry with Pexgol

|

Meltdown Water Transport

|