Replacement of a Steel Spool with Pexgol

Substitution of a Steel Spool for PE-X Coated for Pumping Formation Water.

Estudo de Caso Nº

106

Cliente

Enap Sipetrol

Ecuador

|

2021

Condições de Trabalho

Pressure: 10 PSI | Temperature: 71°C / 160°F

Solução Pexgol

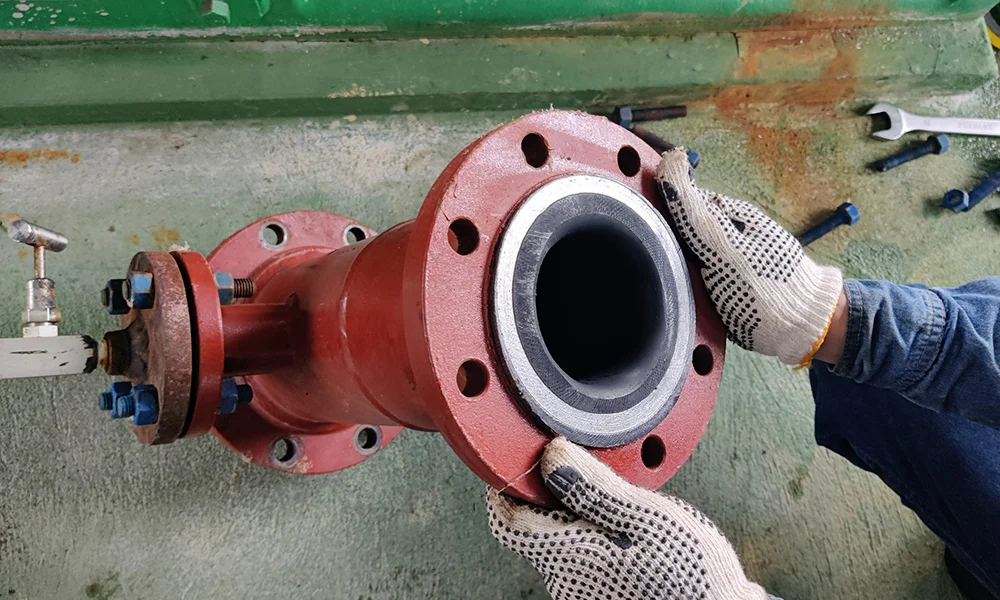

6”x4” steel eccentric reducer coated in Pexgol

Aplicação

Formation water pumping

Comprimento

n/a

Categorias

The Challenge

Enap Sipetrol Ecuador, is a branch of the Chilean state oil company Enap, is the operator and owner of 42% of Block 28 in the southeastern area of Ecuador.

In their process plant where it was necessary to transport formation water, they had a steel spool coated internally with epoxy paint and it corroded easily due to the aggressiveness of the fluid.

Pexgol Solution

The client decided to replace the steel spool with Pexgol. It was installed in October 2021 and inspected in March 2022 and no type of corrosion or adhesion of solids was observed.

Estudos de Caso Relacionados

Underground Mine Dewatering

Codelco Chuquicamata

Chile

|

2017

Overcoming Installation Hurdles and Enhancing Operational Efficiency

Newmont

Argentina

|

2022