Innovation in Safety: Pexgol Piping System for LPG Supply

A Case Study on the Collaborative Engineering and Strategic Implementation of the Pexgol Pipeline System for Public Safety and Efficiency

Estudo de Caso Nº

141

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Rawabi, a city located in the Judean Mountains faced a unique challenge: to replace private gas supply with a LPG (Liquefied Petroleum Gas) to the city while conforming to International Standards.

The new gas supply pipe design challenge included:

- High mechanical resistance to withstand high pressures and external wear and tear.

- Continuous sections to minimize connection points.

- Long-Term durability to minimize maintenance, and maximize the return on investment (ROI).

The Solution

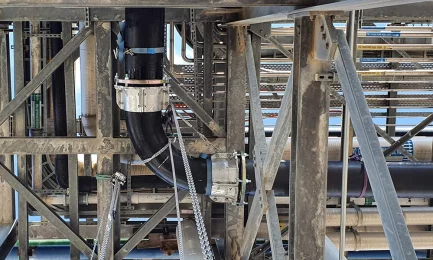

The solution to this complex challenge was found in Pexgol’s Class 15 SDR-11 pipes, with sizes ranging from 32 mm to 250 mm. These pipes were specifically designed for compatibility with Natural Gas & LPG transportation, having been certified to meet or exceed the following standards:

- API 15PX: Comply with the standard

- ISO 14531: Certified

- AS 2492: Certified

- ASTM F2905: Certified

Over four months, Pexgol’s team worked closely with the design group, providing technical guidance and ensuring complete adaptation to all requirements. The success of this project stands as a testament to Pexgol’s commitment to innovation, collaboration, and safety, contributing to a future where the residents of Rawabi can live without the concern of private gas tanks and enjoy the benefits of a safe and efficient public gas supply system.

Estudos de Caso Relacionados

Implementation of Pexgol Pipelines for the Transport of Muddy Water

|

Industrial Waste Water to MBR Treatment Facility

|

Palm Oil: Transport of Leached Mud

|