Efficient Implementation of NaOH Drainage Systems

Profertil and the Adaptation to New Chemical Processes with Pexgol.

Estudo de Caso Nº

161

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Profertil, a leading company in the production and commercialization of soil nutrients in Argentina, faced a significant challenge at its plant. With the recent modification of their processes to include the discharge of 50% sodium hydroxide (NaOH), it became imperative to develop suitable infrastructure to handle this highly corrosive chemical.

The original unloading system was not designed for NaOH, necessitating the creation of a completely new system capable of handling the unique specifications of this chemical.

The Solution

Profertil decided to implement a solution using a 10-meter Pexgol pipe, leveraging pipes that the company had already acquired for another project. Pexgol was chosen due to its high resistance to chemicals, durability against corrosion,

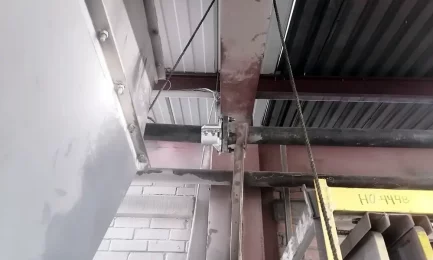

and ease of handling and installation. The project involved excavation and civil works necessary to install and connect the new piping to the collection chambers, followed by paving the surface to ensure the system’s integrity.

The installation of the Pexgol pipe was successfully completed, connecting the collection chambers in the truck unloading area. This system now efficiently handles the excess NaOH and wash water, combining and draining them without incidents. Since its commissioning four months ago, the infrastructure has operated without issues, demonstrating Pexgol’s ability to adapt to Profertil’s specific industrial chemical handling needs.

The client, Profertil, expressed satisfaction with the versatility and effectiveness of the solutions provided by Pexgol, highlighting the quick installation and reduced risks associated with handling corrosive substances.

Estudos de Caso Relacionados

Transportation of Alcohol for the Production of Rum and Brandy

|

Dewatering Through Shafts

|

Improving efficiency in steel foundry with Pexgol

|

Water Drainage at an Underground Mine

|