Slurry Transportation

Transport of acid slurry at high temperatures

Estudo de Caso Nº

12

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

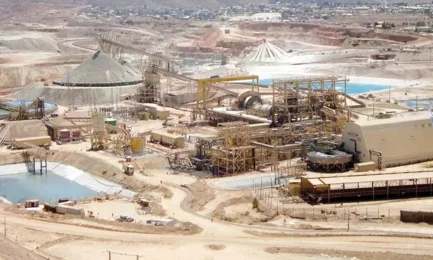

The Challenge

Moa Nickel required to transport highly abrasive liquid at high temperatures.

At the beginning they used fibre-reinforced plastic pipes, that later suffered damage caused by the abrasion. Furthermore, they used polypropylene pipes that didn’t work either, they couldn’t resist neither the abrasion nor the high temperatures.

The former pipes were short combined sections that required reinforced foundations and were very hard to install. The working periods were short because of the constant failures, furthermore, the maintenance cost was high as well.

Pexgol Solution

Once the client evaluated the operative conditions, they decided that Pexgol pipes were the best option, thanks to it abrasion resistance.

Additionally, special “U” pieces were developed for the client, made of steel with internal Pex lined.

After the installation, the Pexgol pipes operates perfectly till today, in excellent conditions and reducing head losses.

Estudos de Caso Relacionados

Water Drainage at an Open-Cast Mine

|

Water Extraction from Wells

|

Compressed Air Transportation

|