“Threading” Pexgol Pipes

Optimization of Water Systems in the Energy Industry.

Estudo de Caso Nº

160

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

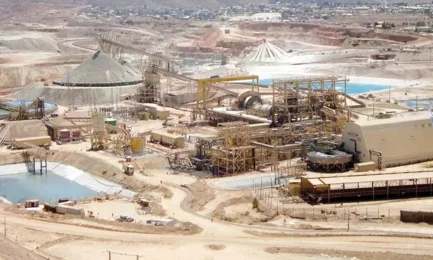

Pluspetrol, an international company with extensive experience in oil and gas exploration and production, faced a significant problem with one of its water pipelines in Argentina. The existing carbon steel pipe, used to transport fresh water, showed evident signs of wear due to corrosion and blockages caused by scaling, compromising the efficiency and safety of the water distribution system.

The Solution

To address these issues, Pluspetrol decided to replace the existing pipe with 160 mm, class 15 Pexgol pipe, extending over 850 meters. Pexgol was chosen due to its high resistance to corrosion and its ability to resist scaling, in addition to its lightness and ease of handling, which allow for quick transport and installation.

The installation of the new pipe was carried out over a period of two weeks. During this time, a specialized procedure was developed to integrate the Pexgol pipe within the existing steel structure every 220 meters. A specific tool was

designed to advance and dismantle blockages caused by scaling, working in coordination with the municipality to ensure compliance with all necessary permits.

The implementation of the Pexgol piping system in Pluspetrol’s aqueduct offered multiple benefits. The rapid installation and flexibility of the material allowed for efficient integration without significantly disrupting daily

operations. Pexgol pipe, known for its durability and corrosion resistance, promises a long lifespan and a notable reduction in maintenance costs.

Additionally, the use of connections such as the double mechanical connector and flanged coupling ensured a safe and effective installation, adapted to the technical demands of the project.

Estudos de Caso Relacionados

Water Extraction from Wells

|

High-pressure fluid transport

|

Transport of Hot Air for Advanced Agriculture

|

Pexgol Piping for Fire Network System Expansion

|