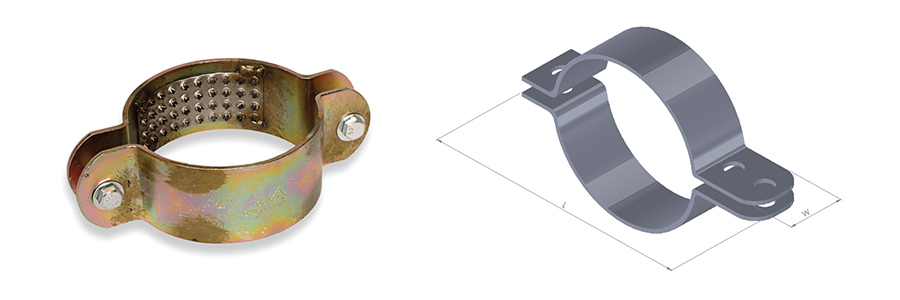

FIXPOINT CLAMPS

| Catalogue Number | Pipe Diameter | L (mm) | W (mm) |

|---|---|---|---|

| 66206302 | 63 | 240 | 40 |

| 66207525 | 75 | 252 | 40 |

| 66209003 | 90 | 266 | 40 |

| 66211004 | 110 | 286 | 50 |

| 66212505 | 125 | 294 | 50 |

| 66214006 | 140 | 308 | 50 |

| 66216006 | 160 | 329 | 50 |

| 66218006 | 180 | 349 | 50 |

| 66220008 | 200 | 372 | 60 |

| 66222508 | 225 | 398 | 80 |

| 66225010 | 250 | 422 | 80 |

| 66228010 | 280 | 453 | 80 |

| 66231512 | 315 | 489 | 80 |

| 66235514 | 355 | 529 | 100 |

| 66240016 | 400 | 574 | 100 |

| 66245018 | 450 | 624 | 100 |

| 66250020 | 500 | 674 | 100 |

| 66256022 | 560 | 734 | 100 |

| 66263024 | 630 | 804 | 100 |

| 66271028 | 710 | 925 | 100 |