Switch to Pexgol Reduces Downtime in Molybdenum Concentrate Transport

Pexgol’s resistance to scaling and chemicals delivers consistent operation in open-pit mining.

Estudo de Caso Nº

176

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

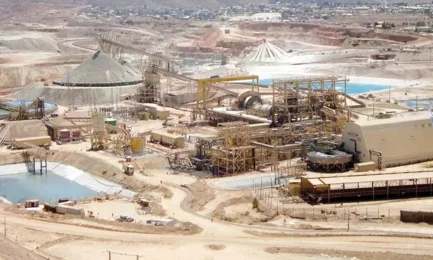

At the Buena Vista del Cobre open-pit mine in Sonora, Mexico, molybdenum concentrate was transported through an HDPE pipeline. This system was regularly compromised by the highly scaling nature of the fluid, which consisted primarily of molybdenite (MoS₂) in a copper-molybdenum concentrate containing Mo, Cu, Fe, S, and Si.

The HDPE pipelines required daily manual intervention to prevent blockages, including frequent hammering along the line to maintain flow. Additionally, sections of the pipe had to be replaced at least once a month due to severe scaling buildup—resulting in high maintenance costs, operational delays, and recurring shutdowns.

The Solution

In 2024, the mine replaced 100 meters of 8” SDR 11 HDPE pipe with Pexgol pipe for its molybdenum concentrate flotation line. Pexgol was selected for its exceptional chemical and corrosion resistance, and especially its superior performance against scaling—a crucial feature given the aggressive nature of the transported slurry and the system’s operating conditions (160–180 psi pressure and temperatures up to 40°C).

The installation was fast and simple, requiring no specialized equipment. The Pexgol coil was unrolled using an excavator and front loader, and the pipe was laid in place within hours. Only electrofusion couplings (EF) were used, further simplifying the process.

Results

After one year of continuous operation, the client reported zero blockages and no maintenance required on the Pexgol line. This has eliminated the need for frequent replacements and cleaning, drastically reducing operational costs and ensuring uninterrupted flotation processes that meet Grupo México’s high efficiency standards.

Estudos de Caso Relacionados

Pexgol for Centrifugal Pump Test

|

Water Extraction from Wells

|

Well Drainage at Mining Dam

|

Efficiency and Durability in Handling Muddy Water

|