From Steel to Pexgol: A Plumbing Upgrade for Tel Aviv’s Gordon Pool

Explore how Pexgol pipe replacement addressed the corrosion issue in Gordon Pool’s saltwater delivery system, ensuring efficient operation.

Estudo de Caso Nº

129

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

The Gordon Pool, a cultural icon and bustling hub of activity since 1956, is nestled in the heart of Tel Aviv and owned by the Tel Aviv-Jaffa Municipality’s Culture and Sports Division. The facility, which features an Olympic-sized swimming pool, an additional pool without lanes, and a children’s pool, maintains water temperatures at 24°C year-round. This unique setup relies on mineral-rich saltwater pumped from an underground well situated 150 meters deep.

The challenge arose from the existing carbon steel pipe responsible for transporting this saltwater from the well to the pools. Despite its traditional use in such applications, carbon steel’s susceptibility to corrosion, especially in environments with saltwater, had resulted in significant wear and tear over time. The worn-out pipe was impeding the efficient delivery of water and posing a significant threat to the pool’s operation, demanding an urgent and reliable solution.

Pexgol Solution

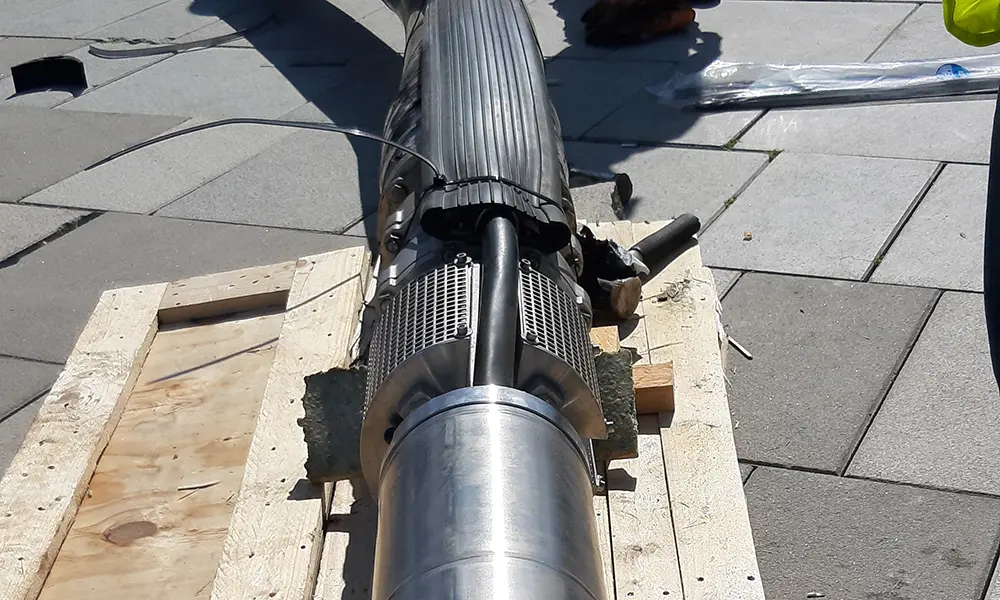

Pexgol 225 mm pipe was selected as the optimal solution for this project. Its resilient construction and superior performance capabilities made it ideal for the Gordon Pool’s unique requirements. The pipe was designed to replace a carbon steel pipe that had previously been in use, demonstrating Pexgol’s versatility and adaptability in various applications.

To facilitate the installation, a special 316 stainless steel nipple with a flange connection was used on both sides of the pipe. The flanged connection ensured a tight, leak-free seal, guaranteeing the pipe’s efficient operation and longevity. The total length of the pipe installed was 24 meters (79 ft), perfectly fitting the project’s scope.

Additionally, a unique innovation by Golan—rubber cable protection—was used in this installation. This creative solution addressed a common issue experienced during similar projects: pump cables getting damaged when the pipe is lowered into a well. By providing robust cable protection, Golan significantly reduced the risk of this type of damage, ensuring a smoother, more efficient installation and operation.

The result of this strategic solution was a fully revitalized Gordon Pool. With the introduction of the new Pexgol pipe and the protection offered to the pump cables, the pool was able to maintain its water temperature at a steady 24°C (75.2° F) all year round, ensuring optimal comfort for its users.

Estudos de Caso Relacionados

Streamlining Water Supply in Highway Construction

|

Potable Water Aqueduct

|