Pexgol Piping for Fire Network System Expansion

How Pexgol piping improved the fire network system infrastructure in a paint manufacturing plant.

Estudo de Caso Nº

127

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Pinturas Wall, a major industrial plant located in Borbollón, Las Heras district, Mendoza (Argentina), produces lines of household and industrial paints, coatings, and industrial paints, with an installed manufacturing capacity of 4,500,000 kiloliters per year. As part of the expansion of their factory, there was a need to expand their fire network system to ensure the safety of their operations.

The project required the installation of a new pipeline that could withstand a pressure of 12 kg/cm² and transport well water at temperatures between 25°C and 30°C. Additionally, the installation process needed to be efficient, minimizing the use of specialized machinery and labor.

Pexgol Solution

For this challenge, Pinturas Wall chose the 110 mm Class 15 Pexgol piping.

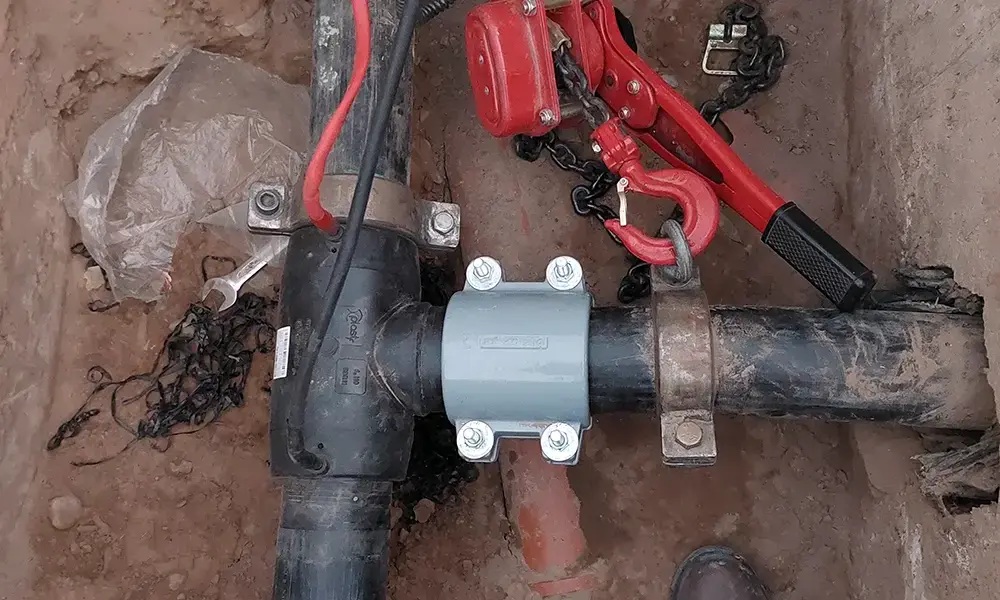

They installed 100 meters of this piping, using a range of accessories such as electrofusion couplers, mechanical double connectors, flanged couplers, stub ends, and loose flanges.

The choice of Pexgol was due to several advantages that this product offered. Firstly, its quick installation, as the laying and cutting of the piping was completed in a single day of work, while the execution of electrofusions and mechanical connections took only three days. Additionally, the piping is lightweight and easy to handle, allowing

it to be unrolled and backfilled with ease, minimizing the hours of machinery use.

Furthermore, Pexgol piping offered long lengths and remarkable material flexibility, further facilitating the installation process. Particularly notable was the ease of using the mechanical connectors, which were simple to install and did not require trained personnel, resulting in significant time and cost savings for Pinturas Wall.

This case study is a clear example of how Pexgol can provide efficient and costeffective solutions for complex challenges in the paint industry and beyond.

Estudos de Caso Relacionados

From Steel to Pexgol: A Plumbing Upgrade for Tel Aviv’s Gordon Pool

|

Transportation of sodium sulfide

|

Pexgol Pipes for Efficient Wastewater Transport

|