Pexgol: Significant Pipe Wall Scale Reduction

The mine was facing scaling issues with their existing HDPE pipes, which required replacement every two weeks. The introduction of Pexgol pipes drastically reduced scaling.

Estudo de Caso Nº

137

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

Introduction

A prominent copper mine in Arizona that uses an in-situ copper ore recovery process, experienced scaling issues in the existing HDPE (PE 4710) piping deployed in the rinse cycle phase of ore extraction.

Scaling in the HDPE pipes caused clogging and despite the use of scale inhibitors and cleaning, some pipes were still being replaced too frequently.

The Problem

Increased operational maintenance and reduced efficiency of the HDPE pipes

created the need for a more efficient, long-term solution.

Pexgol Solution

Pexgol was proposed as the solution for reduced scaling.

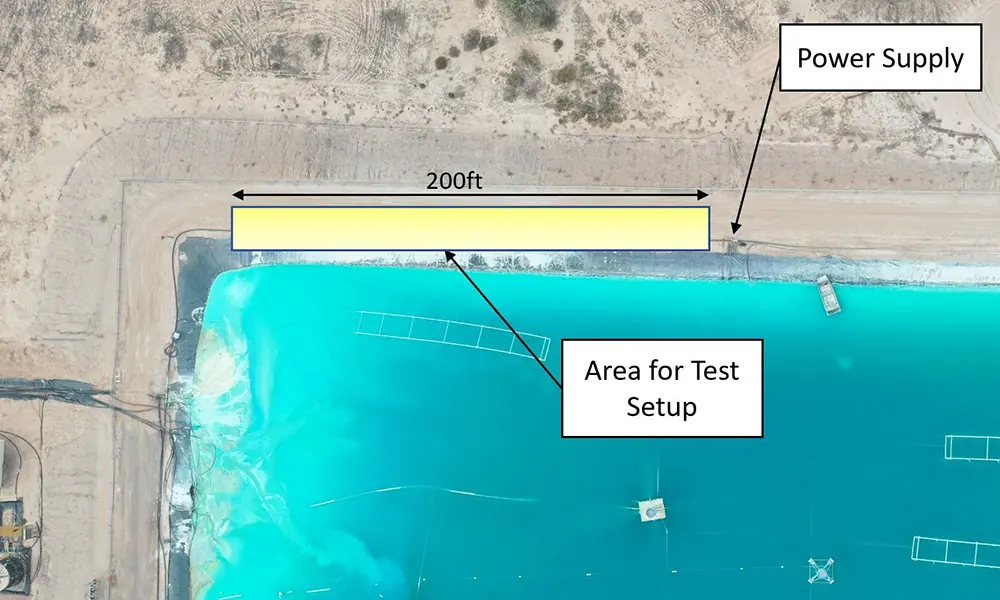

A controlled pilot study was commissioned by the mine to compare gypsum slurry pumped through Pexgol vs HDPE (PE 4710) for a period of 4 weeks.

Various flow velocities, pressures and ambient temperatures were monitored and compared after 2 and 4 weeks.

Results

The Pexgol pipes showed almost no scaling compared with the scaled HDPE pipes after 2 and 4 weeks.

It was recommended that Pexgol replace HDPE at the rinse cycle phase of ore extraction of the mine.

Conclusion

Pexgol pipes are a viable solution for similar slurry applications.

Estudos de Caso Relacionados

Carriage of Chemicals at Sea Port

|

Hot Water Distribution for Solar Technology

|

Meltdown Water Transport

|

Streamlining Water Supply in Highway Construction

|