Improving efficiency in steel foundry with Pexgol

Reduced wear and increased durability in the sand cleaning process at KSB de México.

Estudo de Caso Nº

124

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

KSB de México, part of the KSB Group, a world leader in the supply of pumps, valves, and service, faced a significant problem in their steel casting process. The silica sand used in their molds required a cleaning and conditioning process, being conveyed through pipes from the end of the production line to the filtering system and, finally, to the clean sand hopper.

The main challenge was the wear caused by the sand passing through the piping, especially at the steel elbows, which had a lifespan of only two weeks. Repair or replacement of these components required stopping the filtering line, which affected the efficiency and productivity of the plant. The previously used piping was 3-inch schedule 80 steel piping.

Pexgol Solution

The solution proposed by Pexgol was to implement their PE-X piping instead of the steel piping. The Pexgol piping has a higher abrasion resistance under similar operating conditions to that of steel piping, resulting in a longer lifespan. Additionally, its flexibility and natural bending radius allowed for a smoother path, reducing the load on the system and further increasing its durability compared to steel elbows.

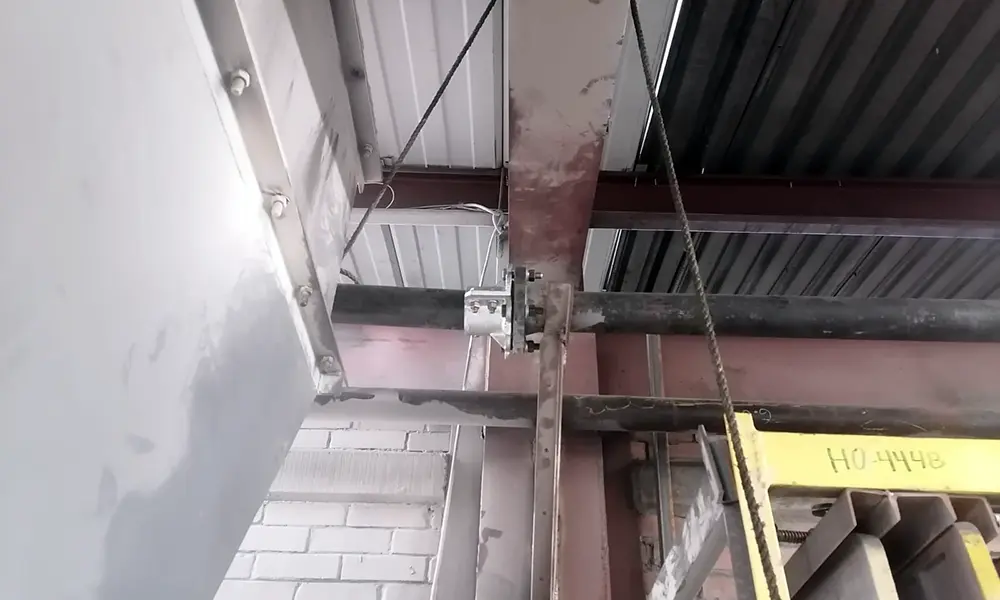

The installation of the Pexgol piping was straightforward and only required two people, without the need for specialized tools or machinery. The GP flanged coupling used in the process is compatible with ANSI 150 flanges, avoiding the need to modify existing connections. Additionally, a load clamp was used at the hopper junction to prevent tube movement during pressure pulses caused by sand transport in the system.

Under the new piping’s working conditions, with a maximum temperature of 45°C and a maximum pressure of 8 Bar, 7 tonnes of sand were transported efficiently and without premature wear on the components.

In conclusion, the implementation of Pexgol piping in KSB Mexico’s facilities provided an efficient, durable, and cost-effective solution, improving the casting process operation and eliminating the need to stop the filtering line for frequent repairs or replacements.

Estudos de Caso Relacionados

Evolving Mine Operations with Pexgol Piping

|

Water Lines – High Pressure Water Feed Lines

|

Well Drainage at Mining Dam

|

Compressed Air System

|